High quality air filter media materials are an important factor which guarantees filtration in the industrial sector. The selection of the correct ePTFE Filter Media for Industrial Dust Removal can have a dramatic effect on the performance and functioning of filtration systems. As to the wholesale purchase, however, how to choose a best air filter media material to ensure effective filtration and meanwhile cost-effective is critical. With a whole heap of options on the market, there are many factors to consider before you decide.

High quality air filter media helps capture most airborne particles and allergens. They are designed to deliver the highest filtration efficiency and dust holding capacity possible, providing you a healthier environment in an industrial workplace. There are many different types of high-quality air filter media materials to choose from, such as fiberglass, polyester, pleated paper and carbon. Each of these has its own characteristics and advantages which make it appropriate for various filtration applications.

For instance, fiberglass air filter media is recognized for its high dust holding capacity and low resistance to airflow, making it suitable for trapping large particles and still enabling good airflow passage in HVAC systems. Polyester air filter media, meanwhile, is highly durable and resistant to moisture, reducing its propensity for wetting out in applications where high relative humidity is present. Pleated paper filter media on a rigid structure increases air flow through while providing high strength for crushing. Active carbon filter media is good for purifying air, removing odors and dangerous gases.

When choosing air filter media material to purchase in bulk for your organization, there are a several important factors to consider that will help you find the best media for your filtration application needs. First, you will want to evaluate the needs for your filtrations system such as what particles need to be filtered (what particle size and type matters), air flow rates (CFM) as well as a filtration efficiency target. That way, you can narrow down your choices and determine the best air filter media material to use.

Second, you want to think about how the filtration system will be operating - if there is exposure to temperature extremes, either hot or cold, high humidity levels and/or excess chemicals in the air. Other types of air filter media may be better at high-temperatures or moisture/chemical resistance. Knowing these characteristics will help you choose a material that is suitable for your application. Vent plugs and Vent Caps are also important components to consider for proper ventilation.

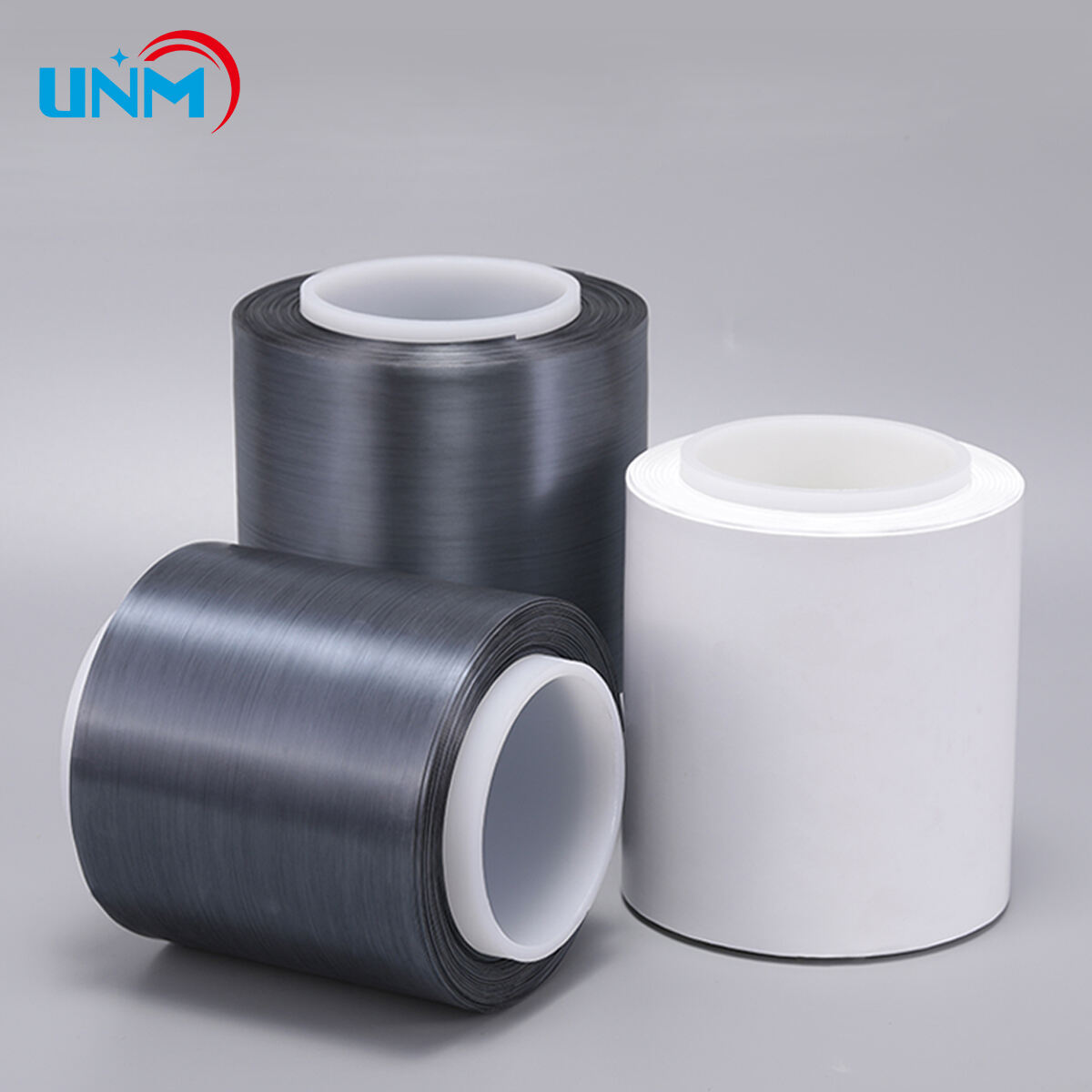

At Unique, we are one of the leaders in air filter media materials with a focus in high quality products that separate us from the rest. Our products are made from high-quality synthetic fibers that resist moisture and can even be washed in warm water! Our media is thermally bonded, conserving energy by maintaining temperature where it counts most - at the air filter. What’s more, our products are totally humidity-and mold-resistant, so they’re perfect for use in damp areas. Our air filter media uses various frame types to provide you with a filtration product that may countered using clean air for the home or business.

A common problem of these air filter media materials is a lack of filtering effectiveness and, therefore, an insufficient purification of the air. In order to not have this issue, you want to select a good quality material like the ones from Unique that are made specifically for filter efficiency. Another problem is the potential clogging of media by dirt particles, blocking airflow and reducing efficiency. If the filter is regularly changing or made of washable materials, this can help to avoid the issue and keep your filter working properly. Choosing dependable air filter media materials and caring for your filter can help prevent these problems so you can breathe easy within your environment.