How ePTFE material can improve product quality

<p>The

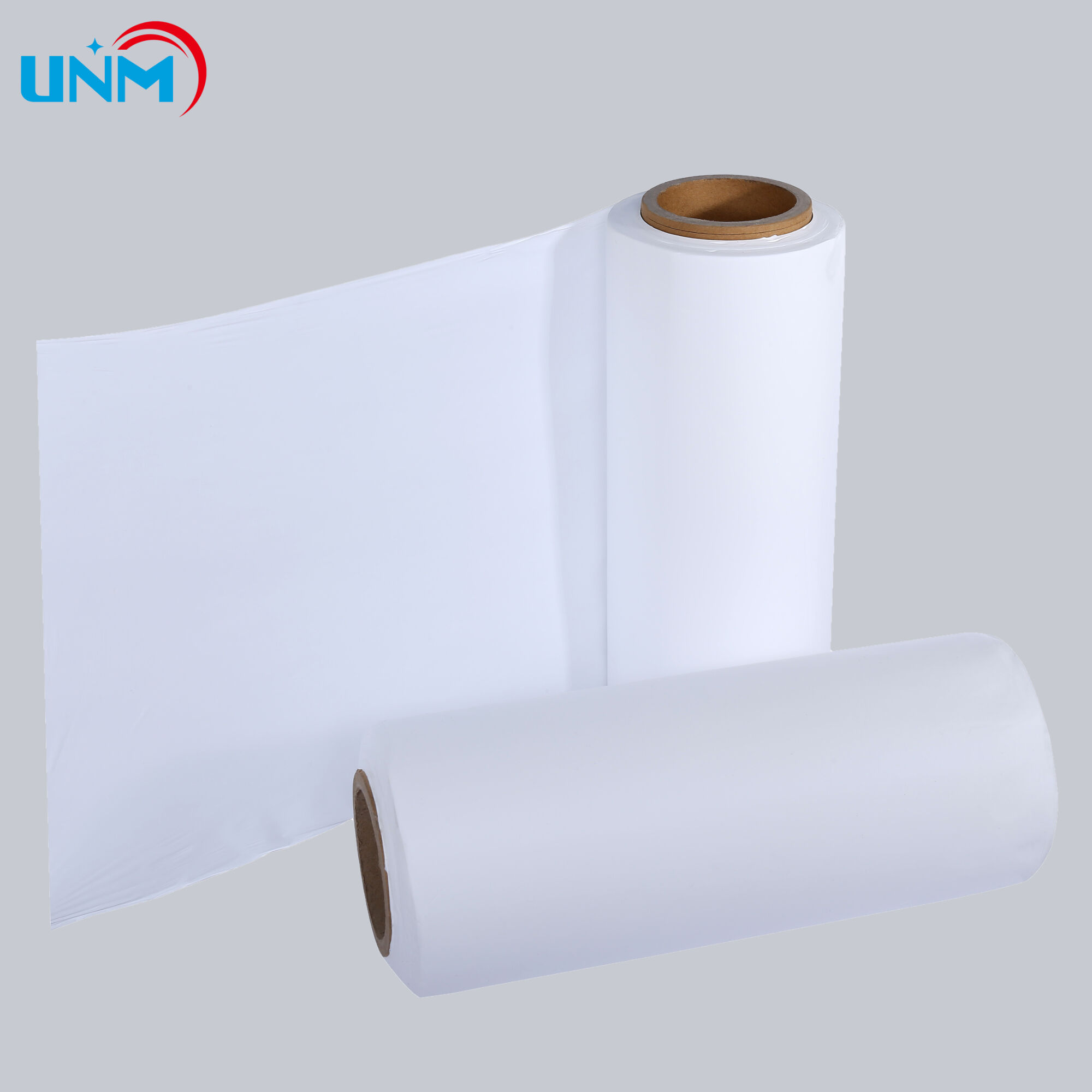

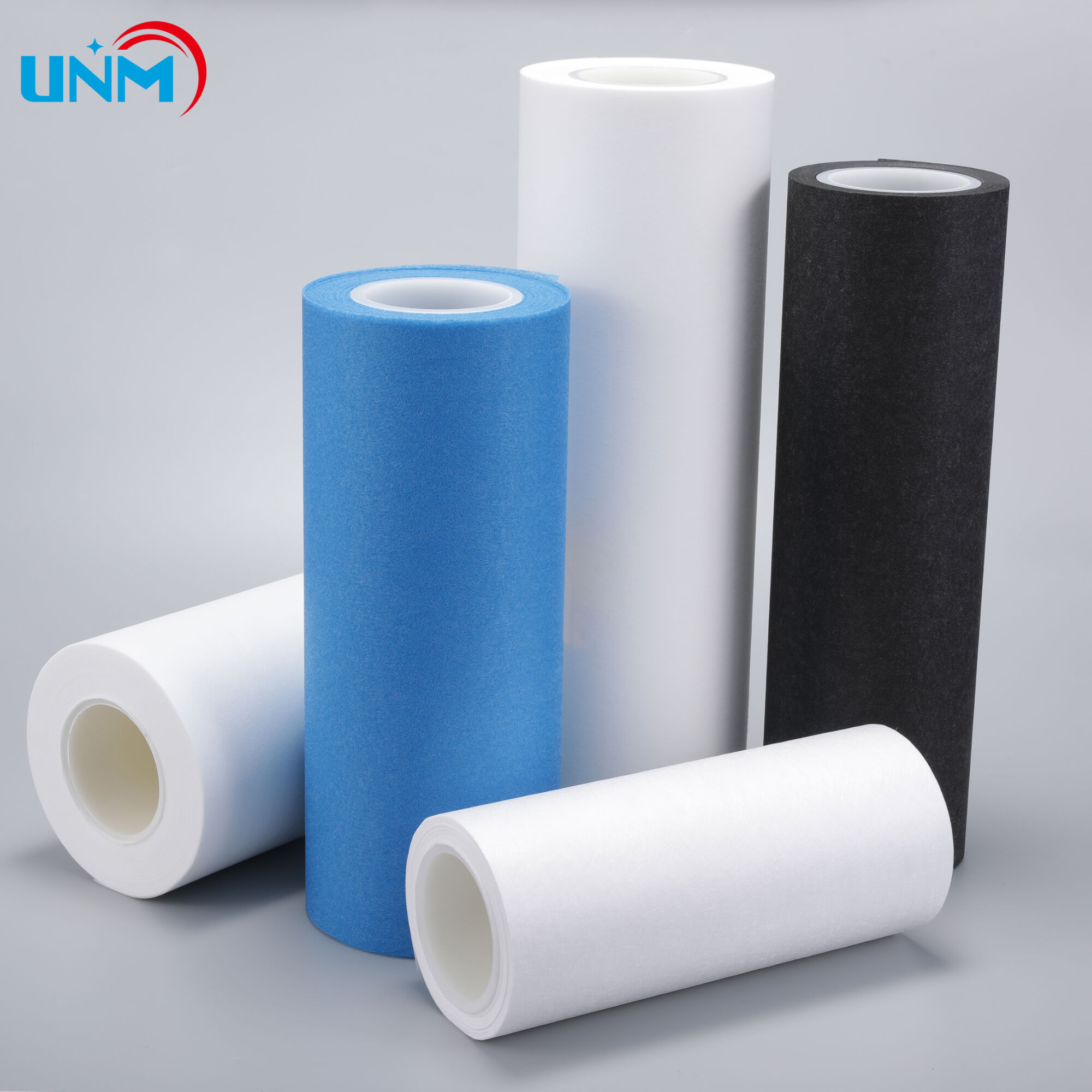

ePTFE Filter Media for Industrial Dust Removal material is a revolution for the high quality products. Its unique chemical resistance guarantees longevity and sustainability for products produced from ePTFE. What this equate to is that components such as gaskets, seals and membranes that are made from ePTFE can maintain their performance even in the worse conditions without deterioration — which translates into a better quality overall product. Also, ePTFE has the non-stick properties that help in cookware to keep food from sticking and burning helped produce a better meal. The properties even of ePTFE can thus be modulated, and products adjusted to individual requirements without difficulty. By adding ePTFE fillers to production companies can upgrade the quality of their products and leave competitors in the dust.</p>