ePTFE (Expanded Polytetrafluoroethylene) Membrane Filter Media for industrial processes is a great filtration material. This peculiar substance has the characteristic property of a nicely developed, porous and uniform-sized pores; it presents as an excellent medium for rapid filtration. The filtration properties of an ePTFE membrane superiorly lend itself to being used in different applications from chemical processing, pharmaceutical manufacturing, food & beverage production and flexible electronics et al.

They offer high filtration efficiency, one of the major benefits you can have with ePTFE membrane filters. The result is a uni-directional bore size distribution in the pores of ePTFE membranes, allowing them to deliver consistent and predictable filtration performance under all conditions - including high flow rates with minimal pressure drop, as well maintaining small molecule cut-off. Besides that, ePTFE membranes provide superior chemical compatibility and it is ideal to be used with variety of fluids/gases in challenging industrial processing applications.

The ePTFE membrane does, however have its limitations. The filters cannot be used for particulate filtration, as pore clogging by particle deposition over time would greatly reduce their efficiency. But because ePTFE membranes are relatively high-cost compared to other filtration materials, they may not be economical for applications requiring a lower solution cost.

On the other side of things, ePTFE membrane filter media work for an array as high filtration efficiency at lower expense. Incorporation of proprietary coating technologies has also helped enhance the resistance against wetting as well fouling tendency of membranes. Besides destroying the microbe growth, these coatings also increase membrane longevity which means you have to replace it less.

An additional innovative technique was incorporated by using ePTFE membranes with multiple layers, which may enhance the efficiency of PBF and decrease clogging possibilities. However, the surface of these high-performance membranes can be altered to carve out tailor-made attributes for a variety of processing tasks.

High performance fine particles are fast becoming significant in both gaseous and liquid filtration applications using ePTFE membrane filter media. ePTFE membranes are found in such gas filtration applications as the elimination of wet air-oil vapors and dry particulates in compressed gases. ePTFE membranes achieve high levels of filtration even at large flow rates and are thus perfect for usage in compressed gas systems as well other types of gas application.

Where ePTFE membrane filters are used for the liquid filtration systems like water, bacteria viruses and other impurities of course in pharmaceutical solutions as well since PTFE membranes provide POROSITY which is a key need when it comes to Filtration-assisting needs without undergoing any aggressive chemicals or tools making them best fit for any Liquid-passing requirements.

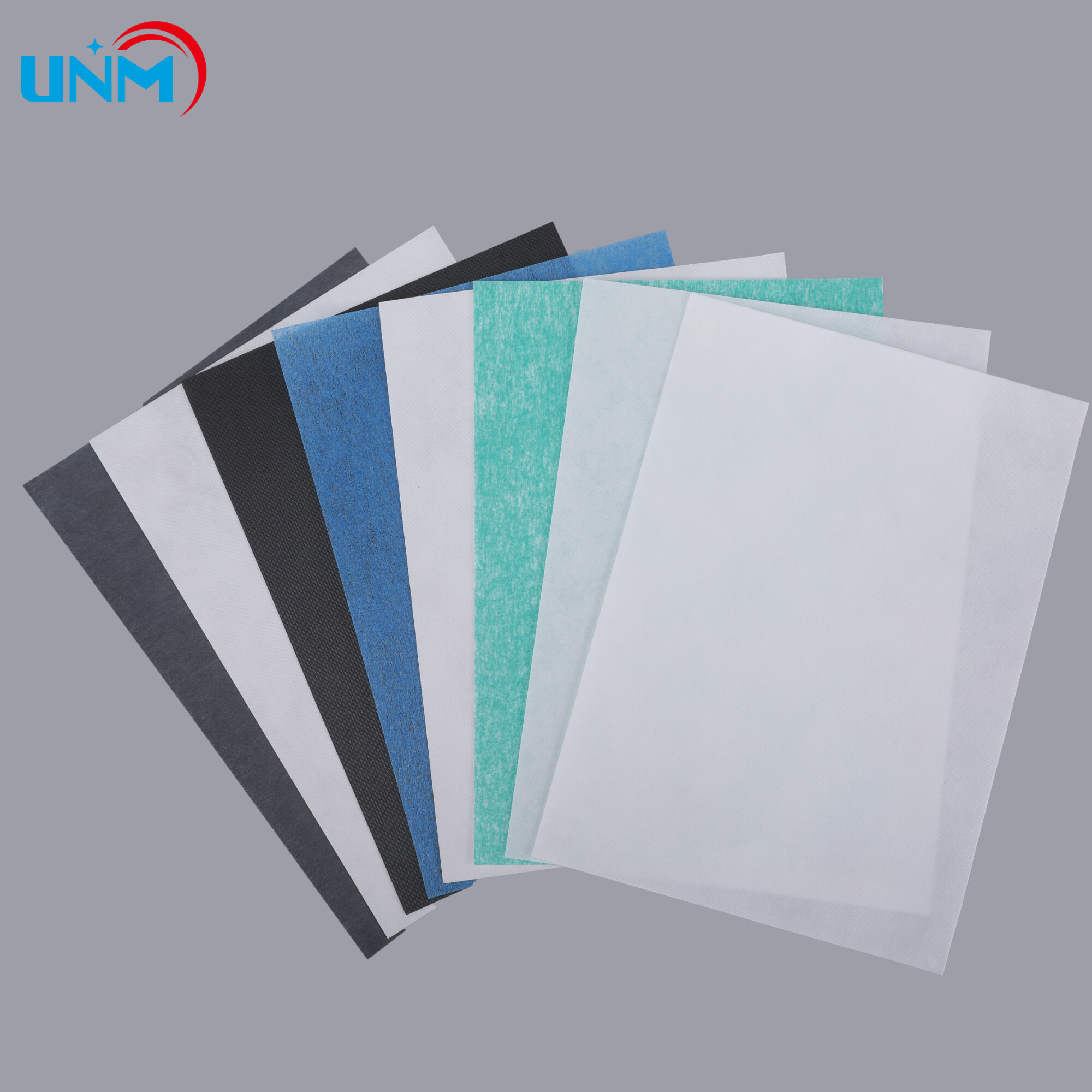

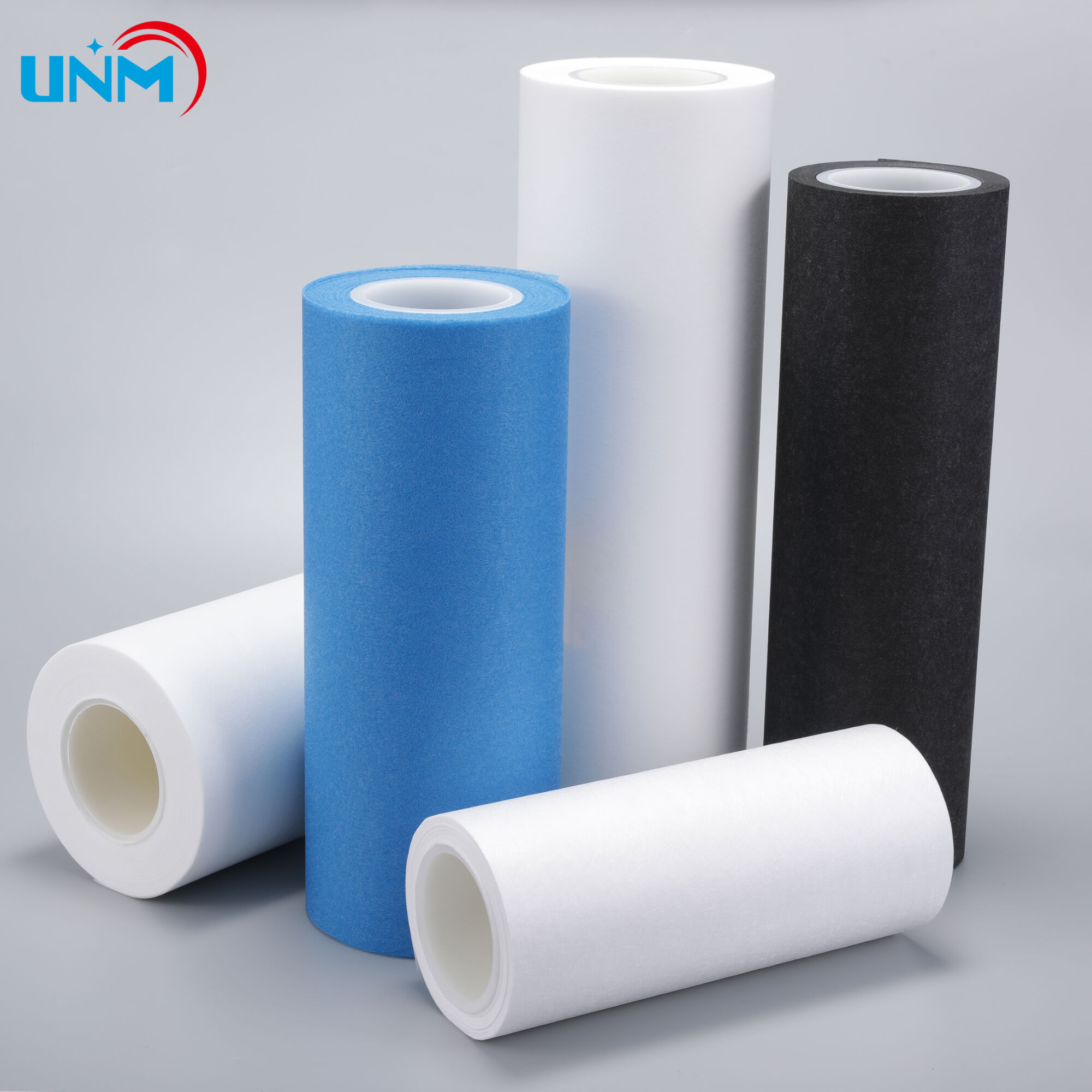

Manufacturers must carefully consider many factors in deciding which ePTFE membrane filter media to use, due primarily to its frequent usage in industrial processes that can affect productivity and maintenance. ePTFE membranes are offered in over 25 different configurations which allow them to be custom designed for applications and particular properties such as filtration efficiency, chemical compatibility or pore size.

It should also address the operating conditions of the filtration system from temperature, pressure and flowrate aspect. These considerations are addressed in the design of such filters so that filtration performance is as consistent and uniform throughout the filter life. Finally, it is the universal and high-efficient filtration media of ePTFE membrane filter. The constant innovation and technology enhancements highlight ePTFE membrane filters as one of the dominant answer in gas & liquid filtration applications for superior efficiency.