Have you ever heard of ePTFE? It is such a fascinating and important material, which can be utilized in diverse ways especially for it to resonate among solar panels. We need solar panels to take the energy from the sun and convert it into what we have been using for millennia in modern technology: electricity that powers our homes, mobile devices. ePTFE is an ideal material for solar panels because it makes them more durable and efficient.

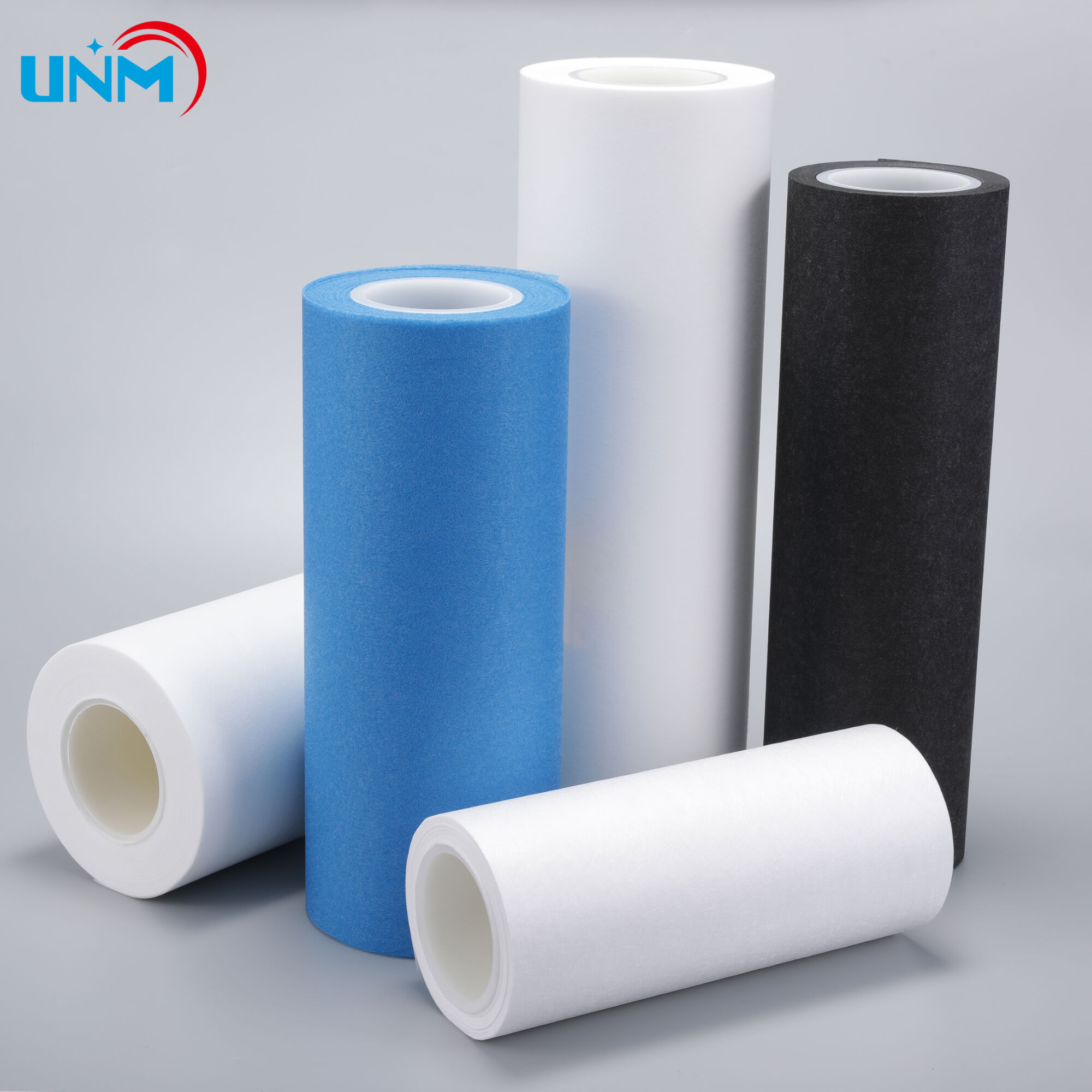

ePTFE: "expanded polytetrafluoroethylene Even if it sounds huge and complex this is actually not that scary! What that means is the material has been elongated but broken apart to create very tiny holes between its fibers. While being extremely light and flexible, these small spaces provides ePTFE with this remarkable tensile strength or durability. While this may sound somewhat mundane to the layman, it means that ePTFE can be put under various pressures without breaking or wearing down.

This is what makes EPTFE so attractive Solar panels. Solar systems have many components and, if any particular part breaks down or stops working then the whole panel may get affected. That would be a big problem! But if we could make solar panels with ePTFE, they would be much more dependable. This means the panels are less likely to degrade, helping them maintain high performance for a longer period of time; ePTFE also helps protect against damage.

You know, when you looked up at the brightly shining sun before and were like: man it would be awesome if we could somehow harness all of its energy to power our homes & cities? Well, guess what? We can actually do that! What is a solar panel and how does it work? This electricity can be utilized to light up our homes, recharge our mobile gadgets and run out appliances.

Solar panels have taken huge steps forward over the past few years and one of the most encouraging has been their newfound usage for ePTFE film. Because of this unique film, the solar cells - which would be nailed by weather and sunshine in normal conditions without them if they were simply glued to a roof -are either completely peeled off from storm damage (if not there), or doing weaker due to destruction originating on their back.

Furthermore, ePTFE film is a high temperature resistive material -a highly critical trait for solar panels. Solar panels heat up a great deal in hot climates which can decrease their power output over time and cause them to break down more quickly. By using ePTFE film, the panels are able to run cooler and keep running at the same efficiency for a longer period.

One of the vastly considered and interesting source among all such sources is Solar energy.ePTFE solar module film shows a step towards clearer and natural tomorrow. Through solar panels with enhanced strength, efficiency and dependability characteristics of ePTFE film are featured making it easier for us to obtain an affordable access on this renewable energy.