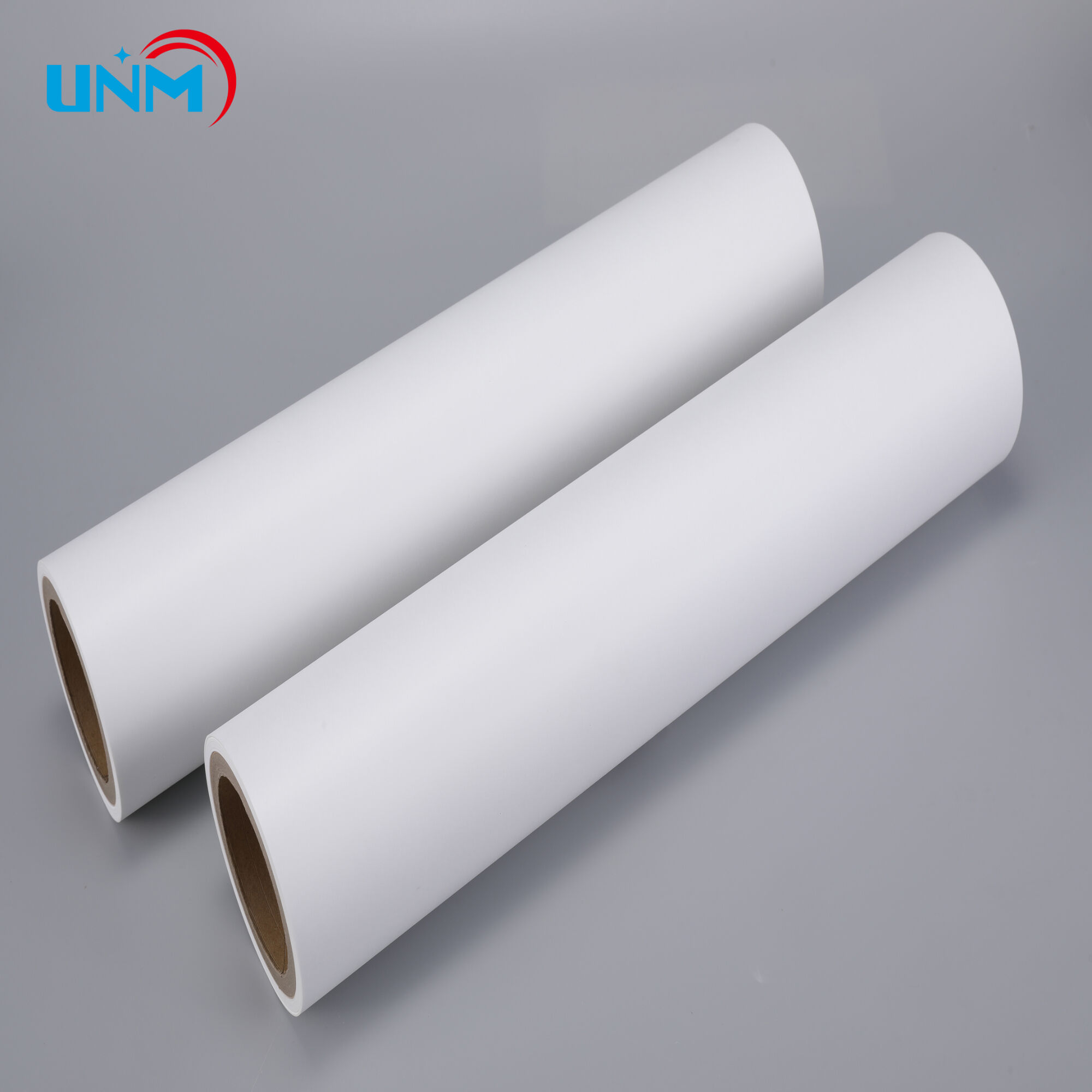

Polyethylene terephthalate: Polytetrafluoroethylene Membrane Filters. An Unrivaled Filtration Systemscheduling partner It is typically used in manufacturing non-stick cookware and medical devices. But, even though those are the most common uses for it-it also has many filter applications. Tiny openings are created in a thin layer of the molded polymerizing terephthalate, which is made into a filter membrane. The HCI Pore size trapping all the elements you do not want, while letting liquid or gas pass through. This is a big deal because this Polymerizing terephthalate maneuver enables to filter out most unwanted stuff from what we want. The polytetrafluoroethylene membrane of Unique is important to point out that Filtration improved tremendously in technology, specifically after the advent of Protein filters around 1950 and became indispensable for numerous industries.

It removes even the smallest particles and bacteria within it.

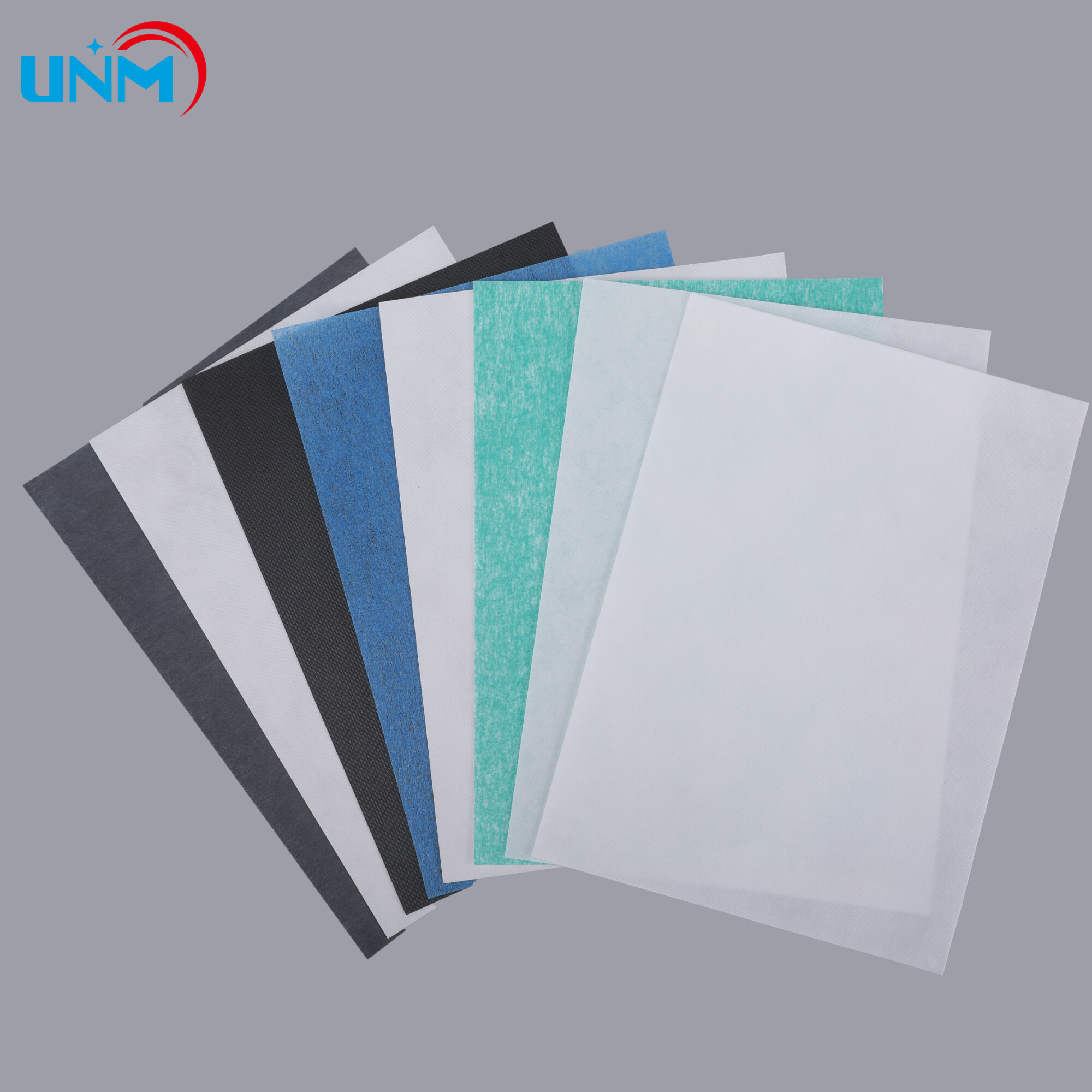

Polymerizing terephthalate membrane filters inherit great resistance to high stress, harsh temperatures and exposure from chemicals. Agrees with most chemicals and solvents. The ptfe hydrophilic porous membrane by Unique are compatible with a wide range of chemicals and solvents, including the ones used in laboratories or for research.

Due to its stability at high and very low temperatures, pressure, chemicals it has become an ideal choice for filtration.

Unlike other alternatives, Polytetrafluoroethylene Membrane Filters are cost-effective. Polytetrafluoroethylene Membrane Filters are useful to many businesses across countless different sectors. Such businesses range from those in the drink, pharmaceutical, and biotech fields to chemical plants or food and beverage industries. Advantage - Increase in the uniformity of goods and Improvement in overall filtration efficiency. It also can use the Polytetrafluoroethylene Membrane Filters. applications of Polytetrafluoroethylene Membrane Filter s across many sectors.

Consumable used in the sterilization process where densely up-difficulty confirmed and rinsing waterproof breathable ptfe membrane from Unique is not difficult.

If used for food, goat would dilute natural products such as wine, beer or dairy juice to be 100% pure-taste Minimum but while combined with other conventional mixes called "Bio-aggregates". Unit seduces the body's driving business.

Electronics and semiconductors-these products are removed with the clean room filtration membrane injecting out of infusing gets a lot more breathing space in to applying these goods.