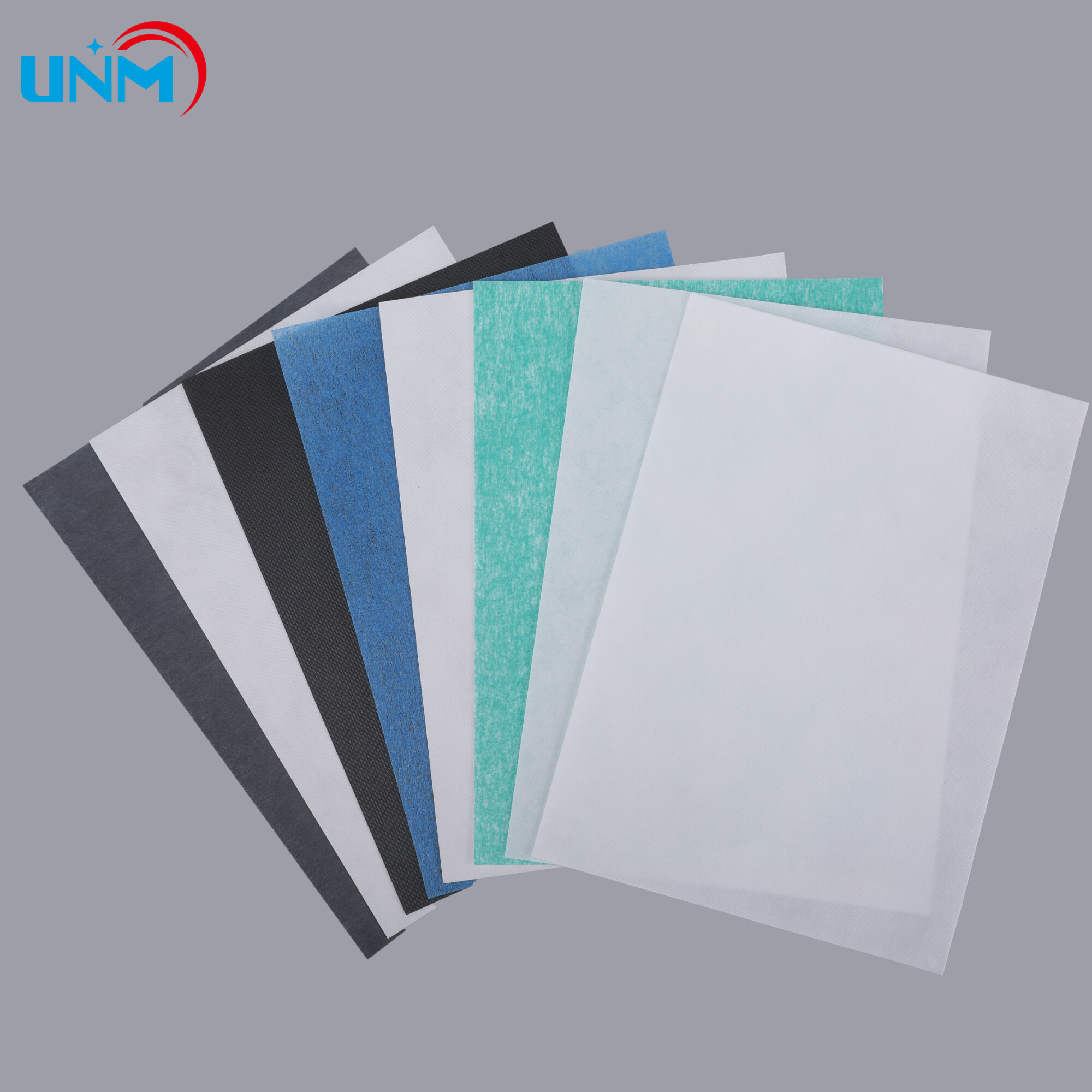

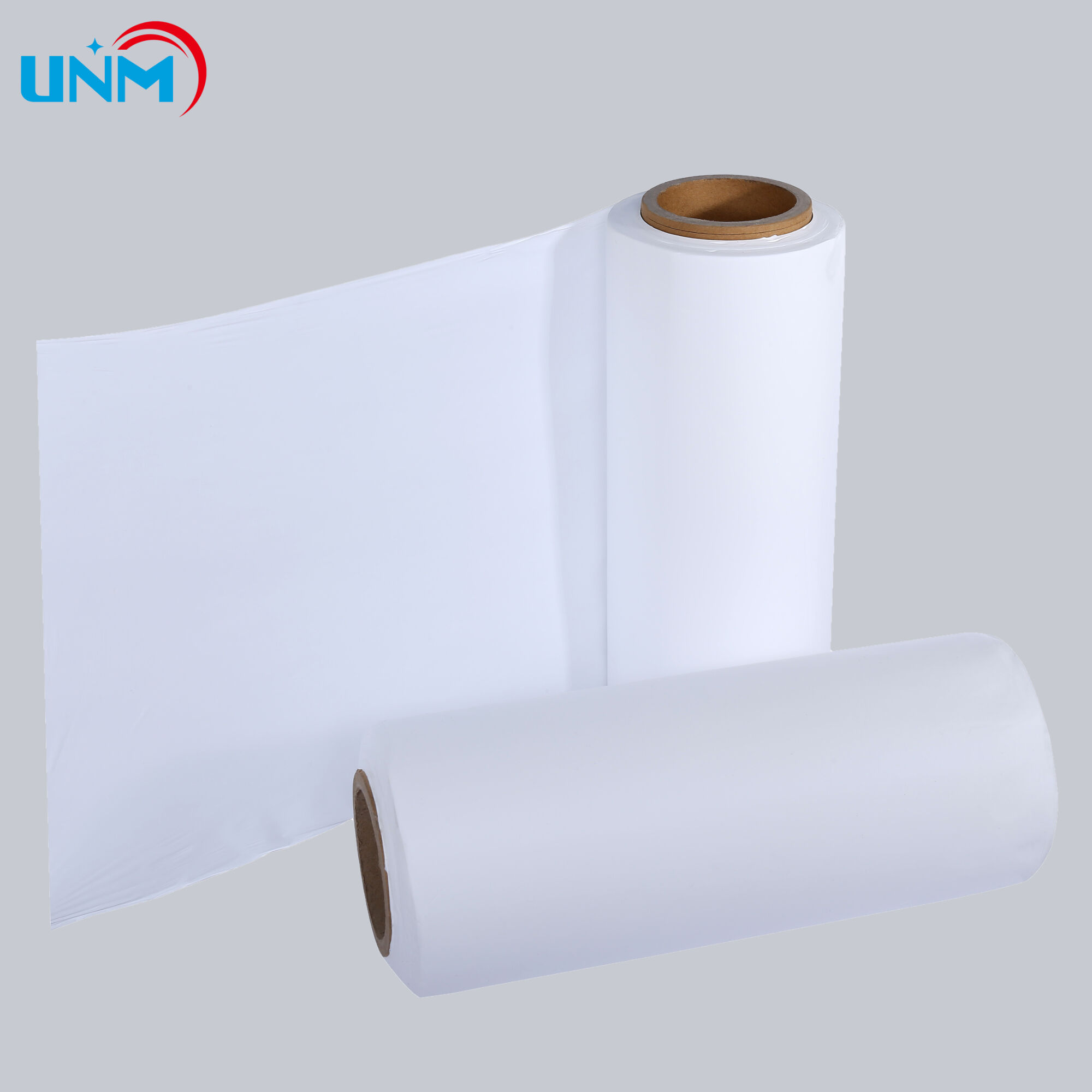

A PTFE membrane is a type of material that used in so many purposes and also for many industries where it can be applied. Consisting of innumerable micro-fibers interwoven and bonded, creating an extremely rigid substance. It is this incredible feature of the material that withstands chemicals. This means it is virtually unbreakable and can handle tough conditions. This means it comes in really handy where other materials might get damaged.

Filtering And Separating: One of the main important application areas that require PTFE THE membrane is filtration and separation. It is therefore used to distinguish one liquid or gas from another. In short, if we want to ensure our water is clean and safe for drinking a PTFE membrane can assist us in removing all the dirt or impurities as well as harmful material from it. This is extremely vital, particularly in regions where the citizenry really needs to drink clean and safe water.

The PTFE membrane is also very lightweight, yet incredibly durable. Which makes it great for stuff like Airplanes where every gram counts. Weight is one of the factors that can make an airplane named Rookie, not fly so great. Another use of the PTFE Membrane is in medical tools where it has excellent longevity properties. It shows that the medical equipments are work good and no break down easily, it is very useful to maintain human healthy.

Are you aware about the numerous applications where PTFE membrane is used? Its application is not only to medical tools and airplanes but, belongs in factories too. PTFE membrane is also used in these factories to keep machines well by eliminating soil and impurity from water other liquid. This is important due to the fact that filthy machines could not function properly. Furthermore, PTFE membrane is widely used in the food sector. It safely separates different parts of food products, making sure the stuff we put in our bodies is healthy and sanitary.

Last but not least, PTFE membrane is an interesting new material. Certainly, physicists and engineers have always been in search for new ways of using it to make our world better. They are finding creative ways to use PTFE membrane that we will be able to solve big issues. For example, PTFE membrane is used for cleaning the ocean or purify air. This should lead to a world which is cleaner and healthier for all of us.