The wonderful PTFE film moves: a stuff to the various businesses

PTFE film rolls are essential in an extensive range of applications throughout several industries. The applications for these would be the all purpose rolls to manufacturing, healthcare and packaging. PTFE (Polytetrafluoroethylene) is the material of choice for PTFE film rolls which propose as a type of plastic well known to its ability withstand high temperature and severe chemical.

PTFE film rolls have a number of advantages. Their exceptional heat resistance is one of the most major benefits. These PTFE film rolls can operate at a temperature of up to 260 degrees so it is widely used in the baking industry. Moreover, these rolls have fantastic chemical resistance and do not react with most chemicals making a perfect material for medical application. Furthermore, these are used in food packaging systems because of their non-stick features.

PTFE film rolls are available in different thickness and sizes can be made according to needs. They come in adhesive and non-adhesive types. The adhesive type is ideal for surfaces that require the film to stick and not come off once on, while non-adhesive has a sticky side meant for things where you can take it back as well without having anything left behind.

The latter stand out as the best protection for preventing chemical spillages and resisting high temperaturesPTFE film rolls They are very long-lasting and can be used in demanding conditions which cause other load bearing materials to crack or wear out. Also, these rolls are waterproof and moisture-proof so that you can use it to securely handle packaging materials while protecting them from water. Additionally, PTFE film rolls are flame retardant which means they will not burn (unless exposed to a burner), nor melt for excellent resistance against high temperatures.

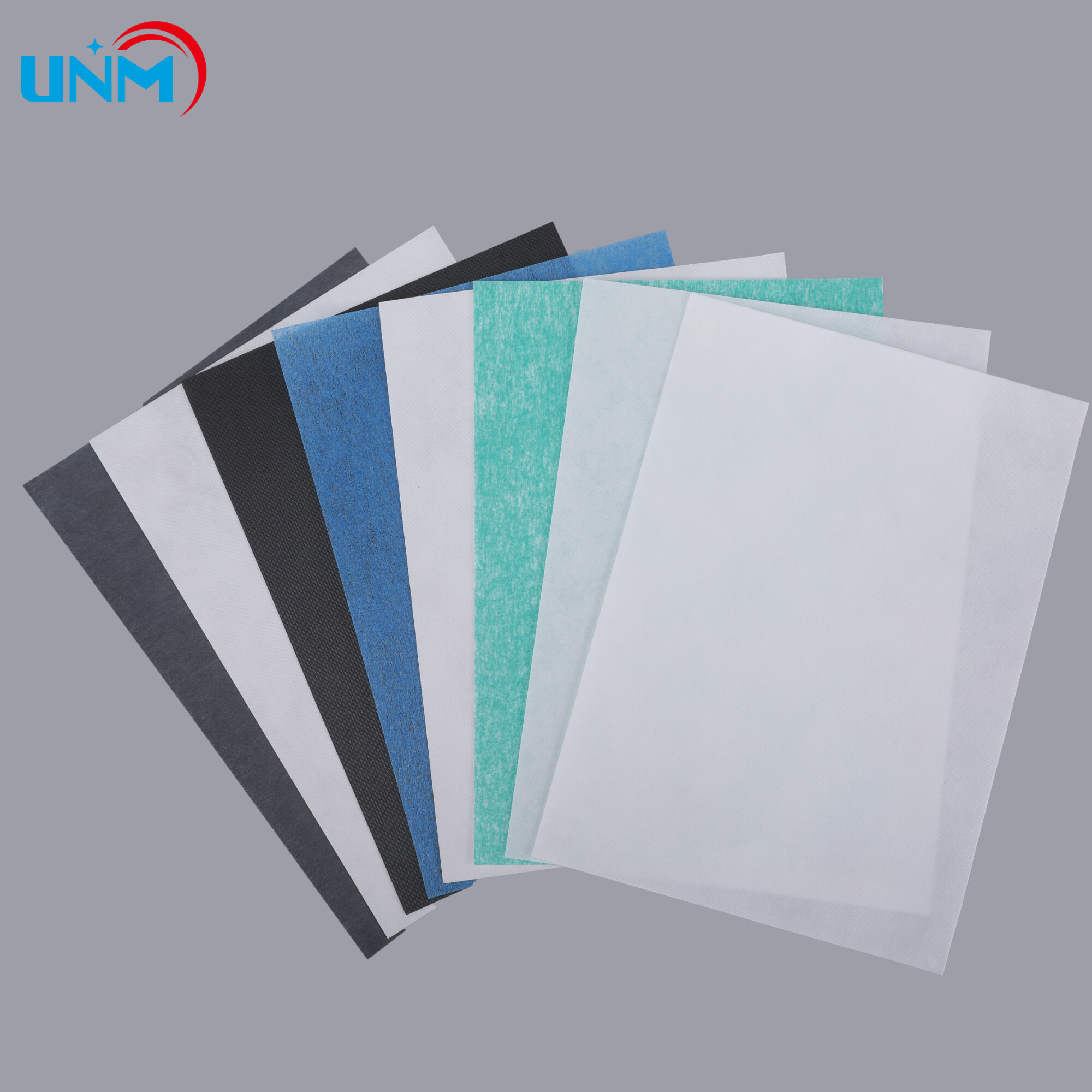

Properties of PTFE film rolls are excellent for a variety - They not only are affordable and simple to use but they also are lightweight, which makes them suitable for packaging materials. This makes these rolls great for brand and marketing using in addition to different customized color available.

Finally, PTFE film rolls are an important material in many industries. Its long list of benefits include heat resistance, chemical and corrosion resistance, strength and durability as well water proofing properties. Having different thicknesses and sizes the rolls are customizable as per application. For those who want cost effective with high performance along the versaility PTFE Film rolls is a best choice. PTFE Film Rolls - The Ultimate For All Industries From Packaging To Manufacturing And Healthcare