If you love the outdoors, nature & all weather play. If you answered yes, then PTFE laminated fabric is for you! It is a wonderful substance that provides all kinds of benefits, allowing you to take part in outdoor activities without getting wet or uncomfortable (in the case for windbreakers). Today we are diving into what makes PTFE laminated fabric so great and why it's a perfect choice for all the outdoor adventurers out there!

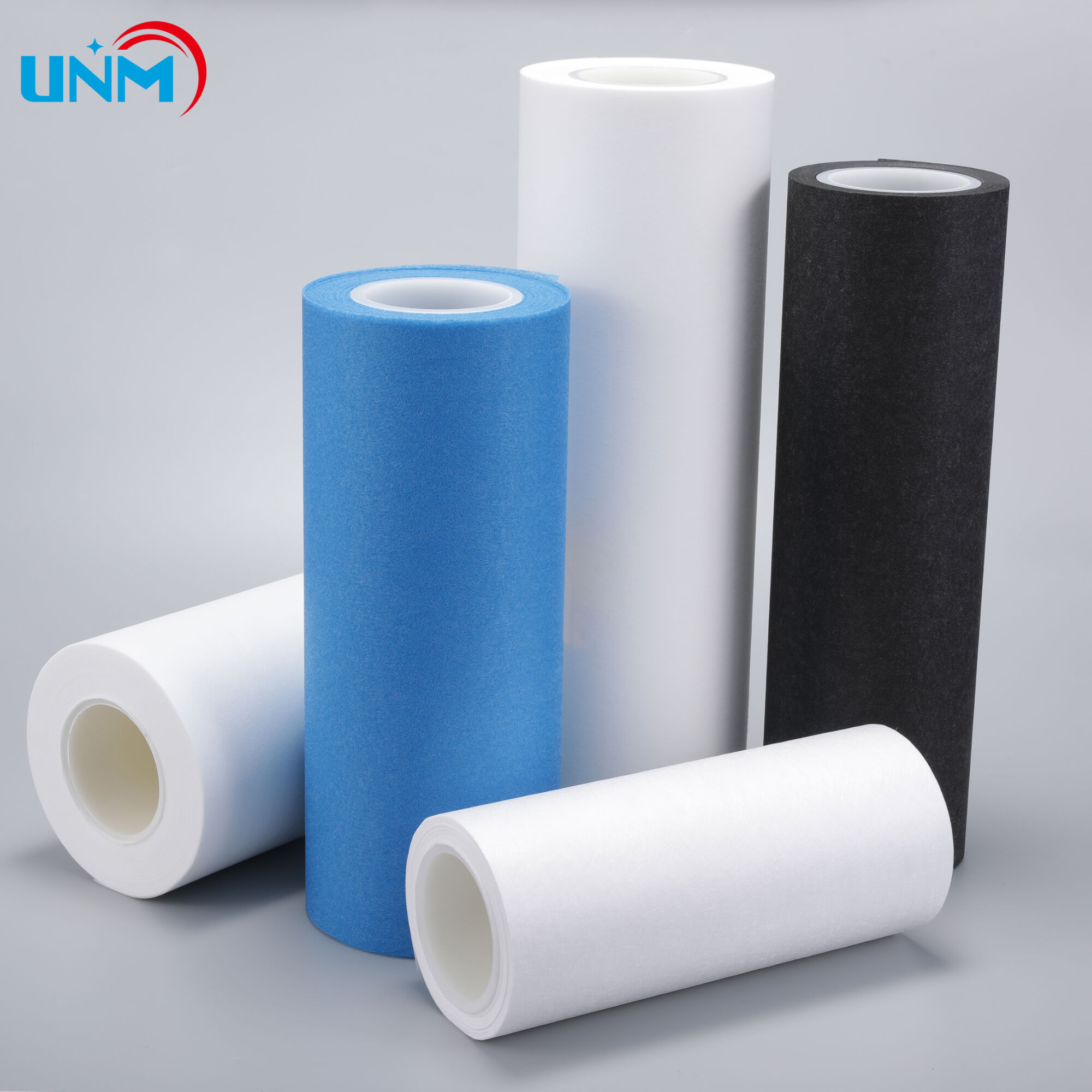

Great for outdoor gear and equipment; PTFE lamination fabric There are a few big reasons for this, with the biggest being water resistance. So when it rains, or you get splashed with water everything puddles on your back and doesn't absorb into the fabric. Instead, it rolls right off! A must-have feature for anyone who loves hiking, camping or other outdoor adventures. Additionally, PTFE laminated fabric is as strong and durable as it gets: so you can do what makes your happy without worrying about the material. From waterproof jacket keeping you dry, robust shelter as your mobile home or trustworthy luggage to carry gear - PTFE laminated fabric is always good!

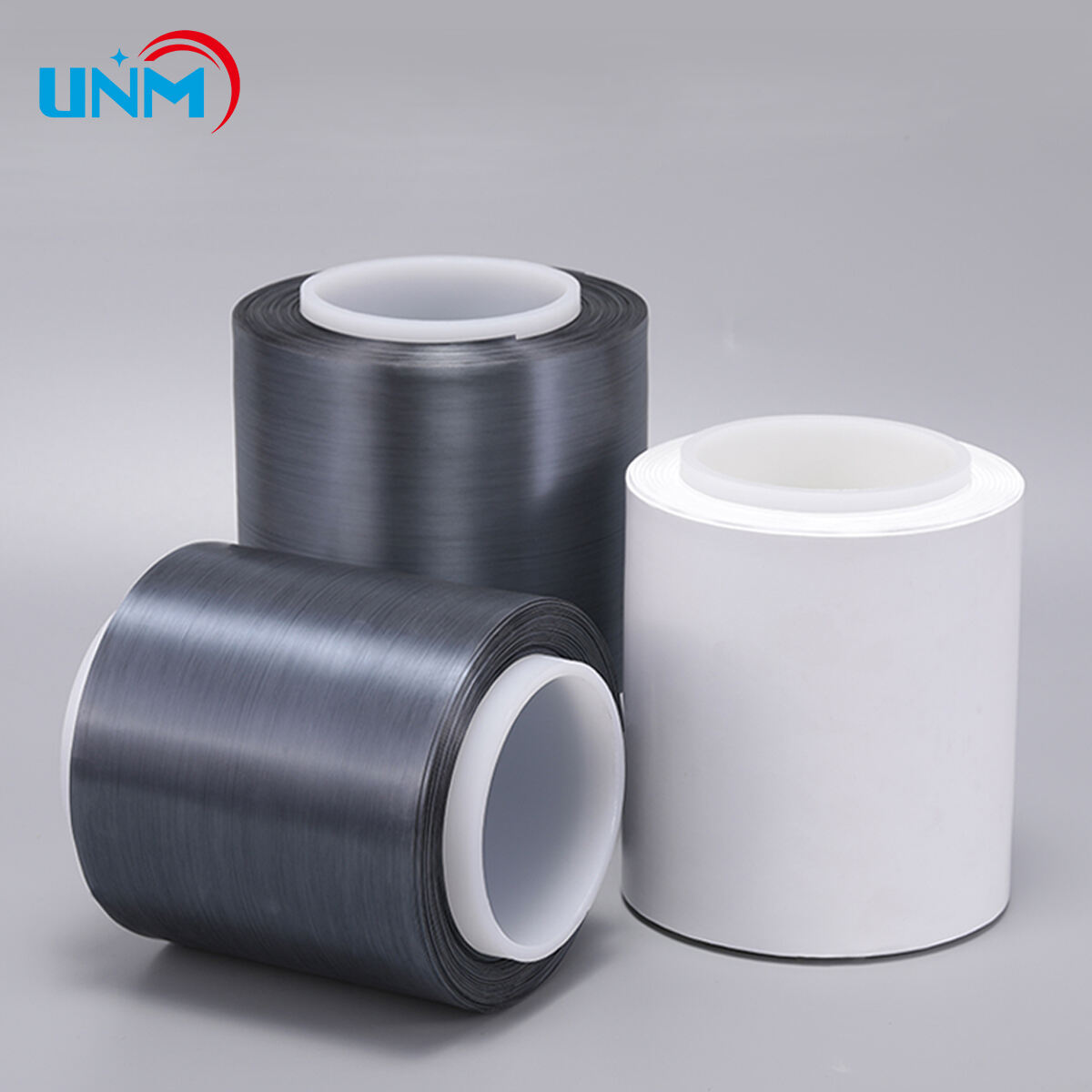

So, what is PTFE exactly? PTFE is short for polytetrafluoroethylene, which is a polymer. Unique and Useful: The magic of pitted polymer is such that it makes high strength PTFE laminate fabric. The fabric itself is equipped with a special PTFE coating layer. This coating helps add to the water repellant nature of the cloth. Moreover, PTFE laminated fabric is too slippy to stick many things. What a time to be alive! Banana fiber, which is super soft and easy to clean, this towel NOT only contains non-animal ingredients but also not typical cotton fibers.

But PTFE laminated fabric have a lot of benefit as not only outdoor gear. The smooth surface of this variety is great for applications where objects are moving, and they can get stuck in the grooves. For example, a conveyor belt which carries goods in factories or other things that need to move smoothly. This smooth motion is important in many cases-machines use pistons to slide against each other with small/tight resistances. In conclusion, for many technical applications PTFE laminated fabric offers very low friction characteristics.

Sure, everybody thinks of using PTFE laminated fabric in outdoor gear. But did you know it works for other applications too? It is actually used in many industries, such as medical and marine. In the medical sector, for example, it is used to produce tools which must be sterilised and suitable for use in patients;and implants that go inside their bodies too. PTFE Laminated Fabric is widely used in the marine sector for making boat sails, ropes and other waterproof fabrics that endure saltwater etc.