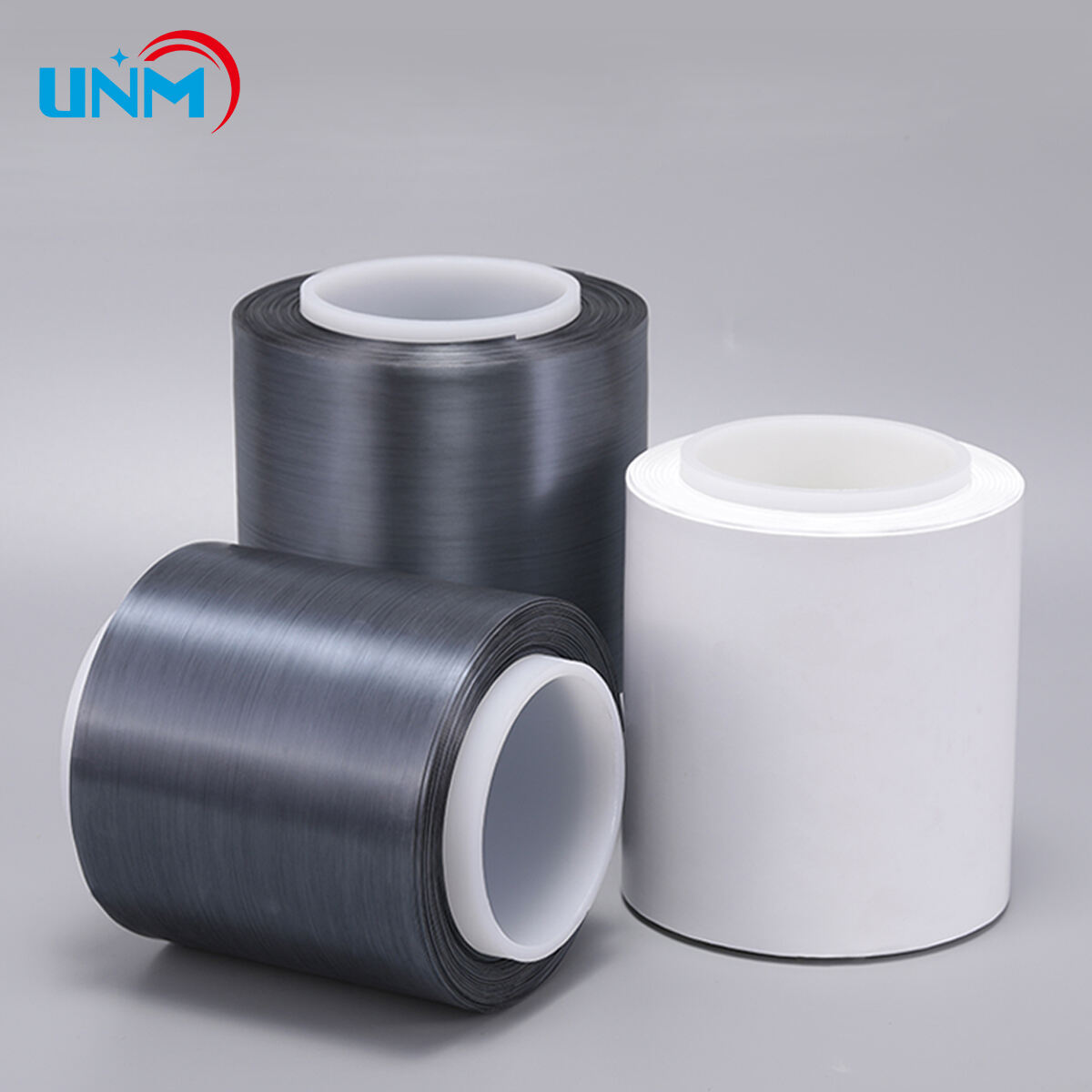

PTFE release film is a special type of plastic that forms an excellent property when it does not stick to items. The jacket of this hose is PolyTetraFluoroEthylene, or in short PTFE. For reference, this unique substance is more heat-resistant and slicker than just about anything else I have yet to touch. As such, PTFE release film is a suitable product for many applications across an array of industries.

PTFE release film has some different things it can be used with, and one of the cool benefits is that could help to make all kind of products It is widely used for the manufacture of non-stick cooking pans, for example. Our PTFE release film means that food slides right off when we cook on these pans, meaning fast and easy clean up. It is also used in factories performing as conveyor belts; so that the items do not get stuck while moving. This keeps the process of production going nicely.

The PTFE release film has completely transformed the function of factories by simplifying activities and providing cost-effective solutions. When PTFE release film first was introduced, factories often used sticky glue to hold things together. Glue tends to get messy and unwieldy, causing problems during the production process.

Factories can avoid use of glue as the sticky issue to our life comes PTFE release film. For example, in the Electronics industry PTFE release film is used to protect fragile circuit boards during production. The film is placed on the board when working with a manufacturer to build this circuitry. From there they can lay the film track, followed by all the other components. After the process has ended and all of these parts have been soldered onto the board, the film allows to be removed without sticking. This increases the productivity of the entire manufacturing process.

PTFE release film can endure strong chemicals and pressures, in addition to providing high heat. Hence the reason it is commonly used when creating intricate, long-lasting pieces. For example, it can be used to make car engine seals and gaskets for oil drilling equipment. These applications are excellent examples of the flexibility and utility to PTFE release film in a wide variety of manufacturing processes.

PTFE release film is so heat resistant, it can even line the inside of ovens and other hot apparatus. This coating creates a non-stick layer which makes it easy to clean after use. This allows it to be used for a variety of products that may need heating, like adhesives or glass parts. This high temperature resistance can give an upper hand on several manufacturing and cooking operations.

PTFE release film could prevent factories using glue at all so customers would never need to worry about the problems of glue anymore. Manufacturers can use the non-stick surface of PTFE release film to temporarily bond their parts together without any glue. This change results in an easier manufacturing process with less fuss from workers.