2.11 Dáileadh méid na mborrcóg i scagairí PTFE ard-chinnte

Staidéar ar an gcomhtháthacht a bhaineann le dáileadh méid na mborrcóg ar scagairí PTFE.

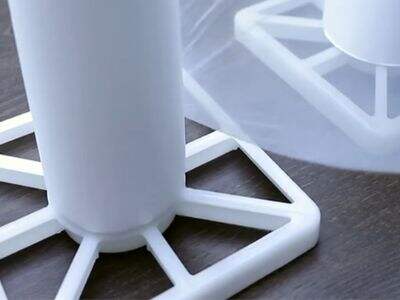

Ar mhaith leat rómhaoin faoi cé chomh beaga is mar a chuirfidh na holcanna seo i scagairí PTFE gach rud in ionad? Na holcanna seo — ar a dtugtar porraí orthu — tá siad chriticiúil don gcineál seicthe a bheith sa scagaire. Is féidir leis an gcaidéal de na porraí seo, agus an méid aonfhoirde atá siad ar fud an scagair, a bheith ag cur páiste mhór ar an gcineál seicthe a bheidh sa scagaire.

Páiriméidir a bheidh ina chúis le poráin cholúin i PTFEs ard-chiníochta.

Tá ilchúiseanna ag baint le dáileadh méid na bpór sa scagaire PTFE. Tá céim mhathúnachta an scagair anseo. D’fhéadfaidh modhanna éagsúla cruthú poráin éagsúla agus dáileadh a chruthú chun éifeachtaíocht iomlán an scagair a mheasctheachtú.

D'fhéadfaí t-oil ag baint úsáide as chomh maith le haghaidh cruthú an scagaire a bheith ag labhairt leis an dáileadh méid na bpóir. Tá PTFE, nó polaitéitrofluóiréitin, in ainmniú coitianta a úsáidtear do scagadh ard-chiníochta mar gheall ar a laghdú agus a seasamh le haghaidh ceimiceál. Cinneann an próiseáil agus an beartúil PTFE méid agus dáileadh na bpóir i dtoradh an tsaothair deiridh.

Is éard a thionlann méid pore dáileadh an scagóraí ar an éifeachtúlacht bainistíocht thrítiam sa scagóirí PTFE.

Is féidir go mbeidh méid na ndamas agus líon na ndamas ar scagaire PTFE éagsúla a bheith ag baint aige le héifeachtacht an scagaire. Tá na damas beaga i scagairí beag-damasach ann mar sin is féidir leo beicthe beaga a bhreith agus mar sin is fearr leo leacht nó gás a ghlanadh. Ach is féidir scagairí le damas ró-bheaga a bheith sáite agus a caillfidh éifeachtacht níos luaithe!

Gan a bheith agamh, is féidir le scagairí leamas móra ceadaigh beicthe móra a théamh ag íoc na glanúlaíochta. Tá sé ríthábhachtach méid damas ceart agus dáileadh a bhaint amach chun an méid is fearr a fháil as scagaire PTFE.

Dáileadh méid damas le haghaidh foréigiúlachta agus oiriúntachta scagairí reabhlóideacha PETF.

Chun go n-oibríonn scagairí PTFE go hionraic, déanann an déantóir an dáileadh méid damas a oiriúint. Trí mhéid damas, chruth agus dáileadh a riaracháin, bíonn siad in ann scagairí láidre, oiriúnacha agus éifeachtacha a chruthú.

Is féidir teicnící chur chun cinn, lena n-áirítear modhálú ríomhairí agus imitheoirí, a úsáid chun méid na ndamas a shaincheapadh. Ligeann na h-inneamhair seo do tháirgeoirí an bealach a mbeidh méid áirithe damas agus caibidil orthu ag dul i bhfeidhm ar fheidhmíocht scagaire, agus mar sin, ligeann siad do tháirgeoirí an dearadh a dhéanamh ar scagaire saincheaptha do riachtanais áirithe éifeachtaíochta scagtha.

Tá an-tomhas ag baint úsáide as an dá chur chuige seo chun anailís agus tuiscint a dhéanamh ar chaoillíocht damas scagaire PTFE le linn teicneolaíocht chur chun cinn.

Is ionann teicneolaíocht stát-ceaptha agus uirlis ríthábhachtach don ainalís agus éisteacht le caibidil méid damas i scagairí PTFE. Is féidir na modhanna cosúil le mamach leictreon scanála agus diffrachtain laisear a úsáid chomh maith le haghaidh taiscéime ar struchtúr na scagairí agus sonraí a thabhairt faoi mhéid, cruth, agus/nó caibidil na ndamas.

Leis na gnéithe seo, is féidir le taighdeoirí tosú ag tuiscint conas a thionlann críochanna na bporeanna ar chumas na bhfiltar. Ligeann an t-eolas seo do chuideachtaí a ndeisíonna filtar a reáchtáil, ag tabhairt torthaí níos fearr do a gcustaiméirí.

Mar a leanas,

Tá críochanna na bporeanna ina fhachtóir ríthábhachtach a thionlann ar an gcríoch a chuirtear ar fhuinneamh na bhfiltar PTFE. Trí na bpointí ríthábhachtacha a chinneann críochanna na bporeanna a thuiscint, conas a thionlann siad ar chumas na bhfiltar, a rogha-chothromú na bporeanna do thurgnimh agus do chumas agus trín teicneolaíocht nuálach a úsáid chun na torthaí a chur isteach, is cosúil go mbíonn bealach ag déantóirí anuas chun na hairgeadais a chur in áirithe le filtar éifeachtach ardchaighdeáin. Nuair a thógfar i gceart leo an comhcheangal ceart críochanna agus foráil na bporeanna, scogán ePTFE tá siad oiriúnach do bhaint amach de ghráinntí neamhchiallaithe, rud a dhéanann iad ina rogha shona don uisce agus ar gheataí soiléir agus sábháilte i ngach áit a n-úsáidtear iad.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

BE

BE

LA

LA