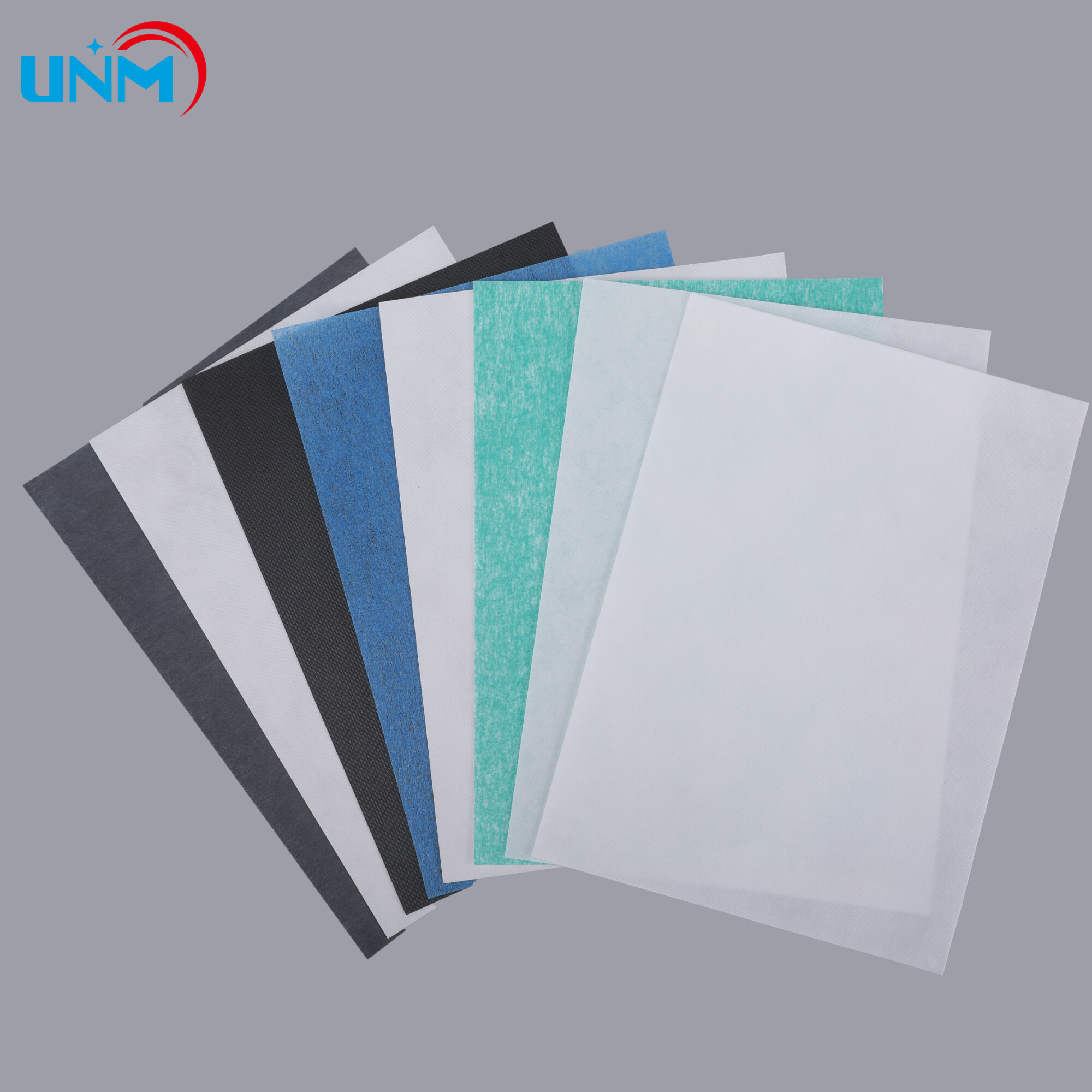

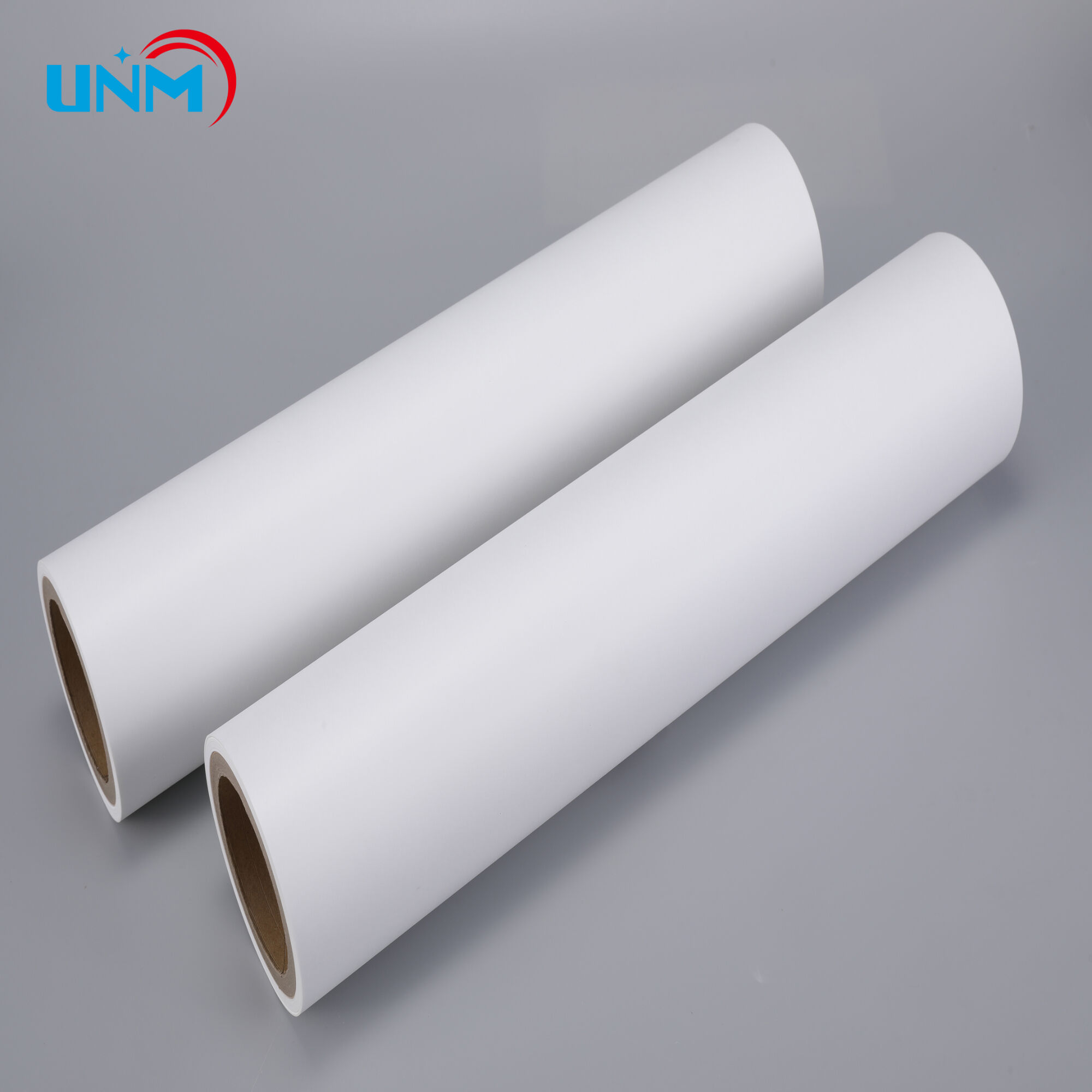

Advanced Applications: New Game Changer Technology ePTFE Membrane Introduction Expanded Polytetrafluoroethylene ePTFE membrane is a unique material that has been used for decades, across multiple lines of business. It has wonderful thermal stability, chemical resistance and low surface friction – low coefficient of friction, the three primary properties that vehicle ePTFE into various high-performance applications. The ePTFE membranes are a stretched, heated expanded form fabricated with the polymer PTFE. It forms a porous structure for improved filtration capacity without losing its robustness. With PTFE Membrane we increased durability and efficiency ePTFE membrane has unique mechanical strength, high tear resistance and imperviousness, highly flexible without any toxicity, and an excellent UV resistance to use this outside. The membrane has a microporous architecture allowing for minimal pressure drop filtration and gives a high flow rate while providing minimal pressure drop in the atmosphere. The robust membrane is tolerant of a highly acidic or alkali corrosive environment and allows the usage not only of acid/alkali solvent but organic solvent usage. The coefficient of friction is low which leads to the lack of accumulation of particles leads to the blockage of the filter which increases their stability in operation throughout a long life period, in which it is a fact that ePTFE membrane has been applied in several filtration schemes, such as air/liquid/gas and dust collector. The membrane has a micro-porous structure for excellent filtration performance and has a good performance availability even in the worst condition, as well as good chemical resistance. The membrane can also be rinsed and the filter element reused, saving money on disposable filters.

Such article of clothing is not only comfortable for the working sector but it also has a wide application in environmental sense, thanks to its range of properties. This property itself makes it a candidate for high-temperature filtration applications, hot gas filtration. Additionally, it is resistant to decomposition and has a long lifespan in the presence of UV radiation (sunlight) or chemicals. Consumable and medical grades of ePTFE membrane are safe for these non-toxic applications. Additionally, its recycle-ability and re-usabilty strengthens the case for sustainable practices in our production choices by lessening environmental fallout as well decreasing waste creation.

Since PTFE membrane are beneficial in the medical field, they have been incorporated as a perfect biomaterial such an- Biocompatibility for Implants, Medical Devices. Otherwise, it (or else) is in use only because of non-toxic and very inert bio-compatible-application stability. The high porosity of the material is an advantage for cells to grow within and as a tool in other fields such as regenerative medicine or wound healing. It also acts as a tissue barrier in some implant devices like ePTFE for artificial heart valves, catheters or grafts to avoid adhesion and inflammation.

The properties of ePTFE membranes, including their high thermal stability; low mass and chemical resistance make them ideal for a variety of aerospace applications. This is the material of choice for aerospace components; wings, fuselages and control surfaces. Low friction means that parts rub against each other gently and do not get stuck. It can also be used as an acoustic insulation material along a sound barrier in aerospace applications.

In conclusion, the ePTFE membrane has been an indomitable tool in numerous fields of a variety of industrial sectors from aerospace to medicine and industries, ever marking new milestones. And because these properties are fundamentally in its structure so it can be diverse material to solve the thermal stability, chemical resistance and filtration efficiency for different applications as this paper demonstrate. It also underscore its crossover credentials with environmental and eco-conscious mindset. It will undoubtedly play a role in creating new technology that can address some of the thornier problems society faces, too.

ePTFE membrane not only has great mechanical strength, but is also durable and resistant to tear. It is flexible and non toxic as well but it also has an impressive UV resistance because of which they use this one in environments outside. Its membrane is microporous to provide efficiency in filtration, minimal pressure drop and high flow rate. In addition, its outstanding chemical resistance allows it to prosper in the corrosive atmosphere with acids/alkalis and organic solvents. Because of a low friction coefficient, the accumulation of debris is kept to minimum level hence increasing performance stability throughout long periods.

The fact remains that ePTFE membrane has been embraced in many filtration applications, such as air/liquid/gas and dust collectibles. The micro-porous structure of the membrane provides excellent filtration performance and its chemical resistance ensures good operational availability also in the toughest conditions. ePTFE membrane can also be washed and the filter element re-used, reducing costs associated with purchasing disposable filters.

Expanded Polytetrafluoroethylene Membrane Brings Sustainability and Eco-Friendly Practices into Adoption

Its range of properties makes ePTFE membrane an ideal option for a variety of applications with environmental benefits. Its heat-resistance and strong construction makes it suitable for a high temperature filtration applications, such as hot gas filtration. It also resists degradation, UV radiation and chemicals for a long service life. Several food and medical grades of ePTFE membrane are available that can be safely used in these non-toxic applications. Moreover, the ease to regenerate and reuse further aids in mitigating environmental concerns as well reducing waste generation.

Effect of PTFE membrane in the medical field are noticed due to which they have been implemented as a right biomaterial such an- Biocompatibility for Implants, Medical Devices. Or else, just because of the fact that it is non-toxic and extremely stable for bio-compatibility as well such applications. Its high porosity is beneficial for cell growth and tissue ingrowth, making it a valuable tool in the fields of regenerative medicine or wound healing. Further, it is also used as a barrier to tissue adhesion and inflammation in implant devices such artificial heart valves, catheters or grafts with ePTFE membrane.

Its properties such as high thermal stability, low mass and chemical resistance make ePTFE membranes suitable for a variety of aerospace applications. It is used to manufacture aerospace components - wings, fuselages and control surfaces. Thanks to the low coefficient of friction moving parts work smoothly and do not jam. It also offers good acoustic insulation material as part of a sound barrier in aerospace applications.

To sum-up, ePTFE membrane marks a milestone as this has been incredibly useful material working in myriad areas of different industrial domains from aerospace to medicine and industries. These properties are inherently in its structure, making it a unique material to address thermal stability and chemical resistance to filtration efficiency allowing it as this paper has shown across many applications. It also reinforces its cross-cutting appeal with sustainability and eco-friendly values. ePTFE membrane will no doubt be employed in developing new technology that helps solve complex problems as well.