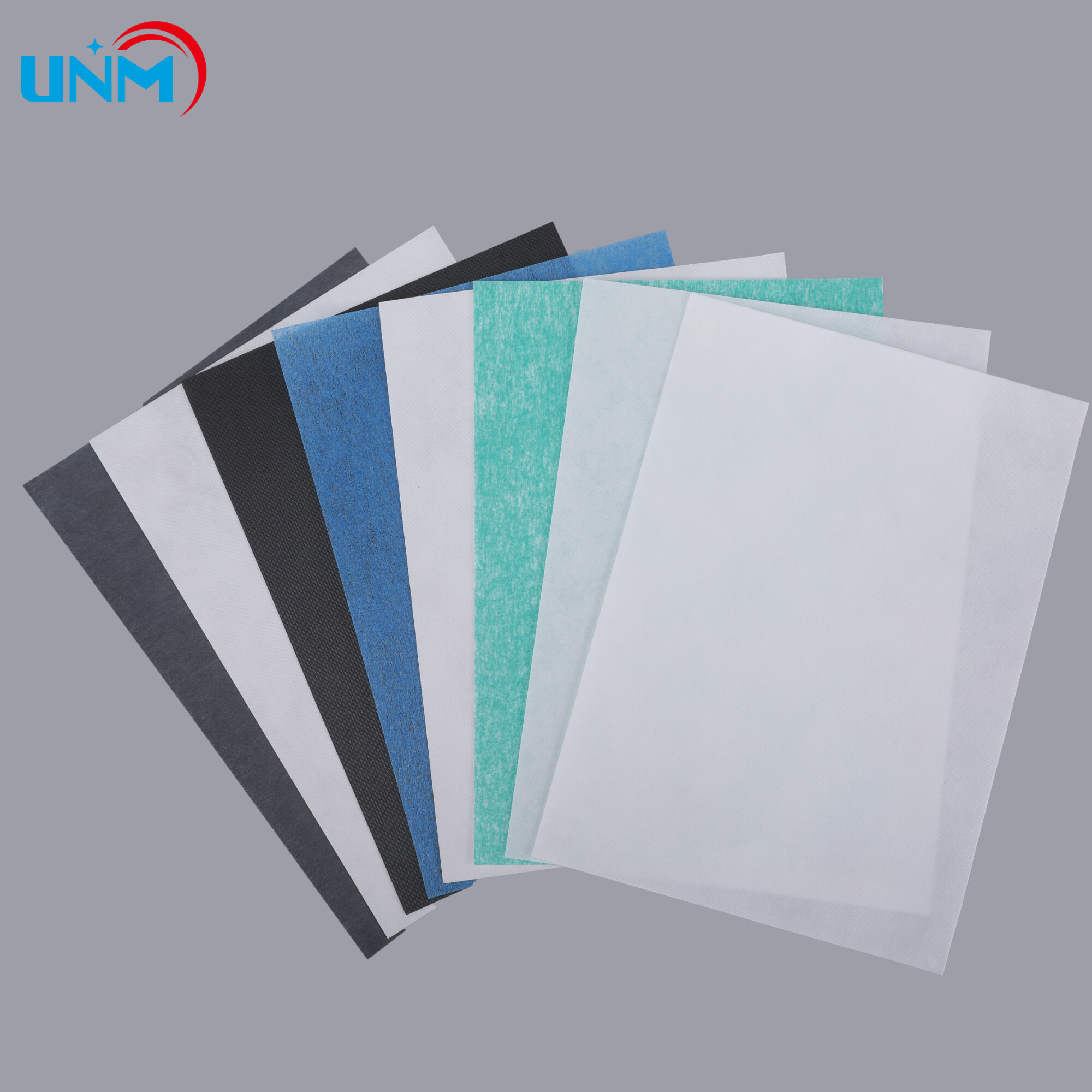

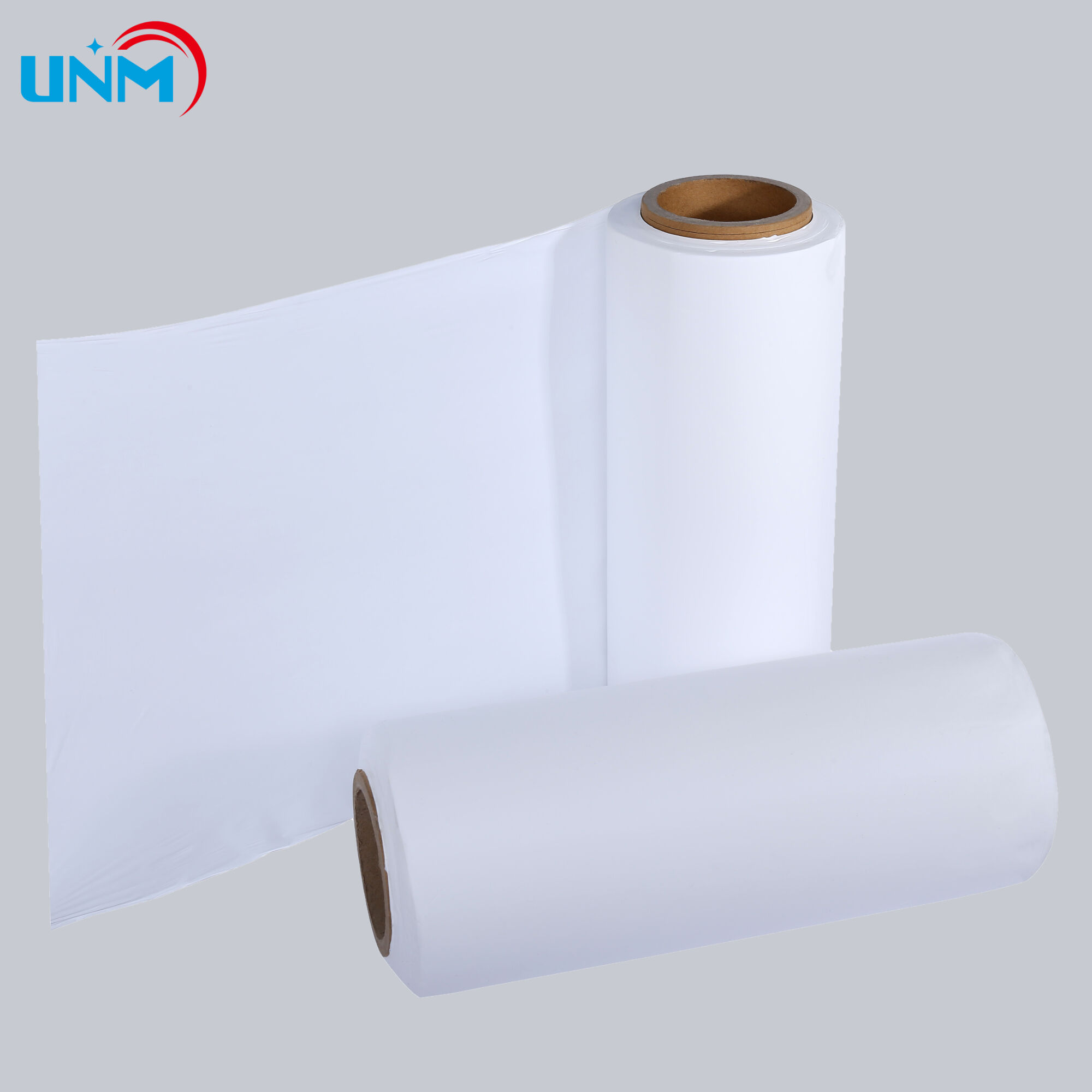

PTFE film sheet is an extraordinary material that comes with a number of advantages for diverse kinds of industrial applications. This unique hybrid material can be extremely useful in a variety of cases due to its benefits for versatility and durability. In either case, when you need to wrap products for safe possessions of simply as a protective layer against dirt and grime that may affect machinery; PTFE film sheet is the go-to option.

Besides functioning as a protective barrier, PTFE film sheet also get melt processed and converted into coatings for pans or wires which clearly shows the diversity offered by this wonder material on creating almost all conceivable product types. Its lightweight yet durable design gives it versatility and makes it a useful tool in Industry

The most notable characteristic of the PTFE film sheet is its phenomenal high-temperature capability. PTFE film sheet is a great alternative to many other materials as it can be easily used in environments with extremely high temperatures, so for example hard industrial ovens or even space shuttles. This heat resistance makes PTFE film sheet suited to industries where the working place is challenging.

In addition, PTFE film sheet has a special non-stick characteristic that makes it very easy to clean and keep up. Whether they are making non-stick pans or tape for packaging from fruits to gadgets, this substance makes sure that items do not inevitably adhere immediately and therefore saves work.

PTFE film sheet also has excellent chemical resistance. Also, this diaphragm resists harmful fluids and gases effectively that are aggressive in nature, therefore it is a very essential part of the industry where different chemicals are working. Whether it is finding use in creating chemical-resistant linings for tanks or producing seals that hold up even under an aggressive environment, PTFE film sheet will always find itself being put to good work in maintaining operational safety and efficiency.

In addition, PTFE film sheet meticulousness and uniformity are ideal for exact applications in the field of manufacturing as well as engineering. These properties facilitate implementation in a wide range of process applications and ensure reliable results with every use due to the ability maintain constant thickness and width.

At last, the PTFE film sheet is proved to be a versatile materials for many different fields with its special properties. High temperature resitance, non stick properties, chemical resistance and consistency of PTFE key reasons behind its popularity in diversified sectors. However, for tough environment and high demands ptfefilmsheet is a reliable solution as it can meet various industrial needs.