Ever wonder how things like air or liquids can escape from different items? Consider a bottle or another container, for example. When you open it... how does air out? This specific task is helped along by something called ePTFE venting. EPTFE Venting: A breathable material this is each wind- and waterproof. It is a special kind of material that allows air, gases and liquids to pass through it quickly without letting harmful particles or poisons out. To know more about ePTFE venting and how it is essential to our day-to-day living.

Uses for ePTFE Venting across multiple industries Cars and vehicles are all about the cars themselves in this car industry, so ePTFE venting here prevents water from accumulating inside the vehicle. This is crucial because it ensures that the electrical parts are not conflicting with eachother which will help them function much better. Materials that are ePTFE Vented is used in medical vices such as respirators and so on. These machines provide life saving assistance with breathing, and require ePTFE venting to contain germs and prevent patient exposure. In the food & beverage industry, ePTFE venting stops things like packages from exploding who have built up gases inside while also preserving freshness and eat safe. Conclusion ePTFE venting is a critical component to many. They help them work more efficiently, stay clean and also make it safer for anyone to use.

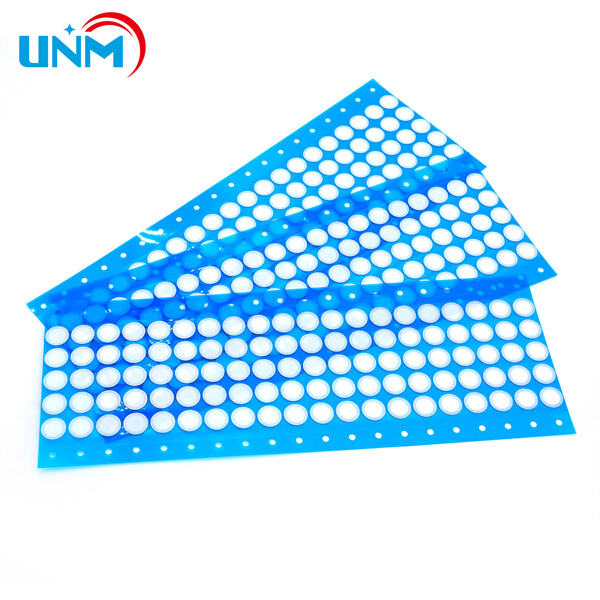

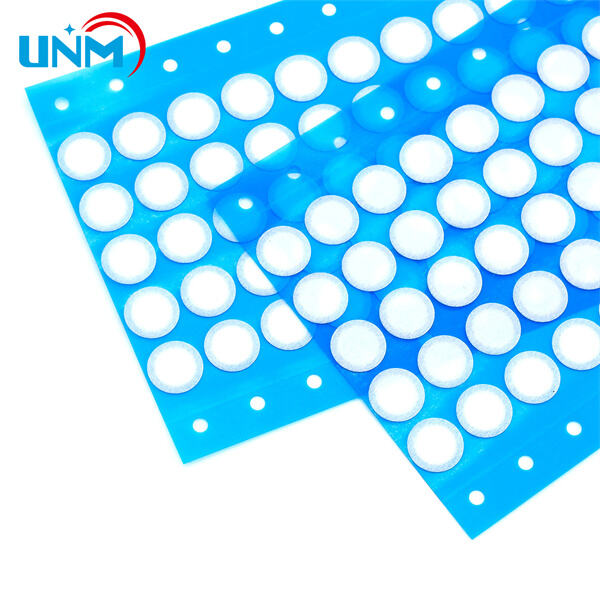

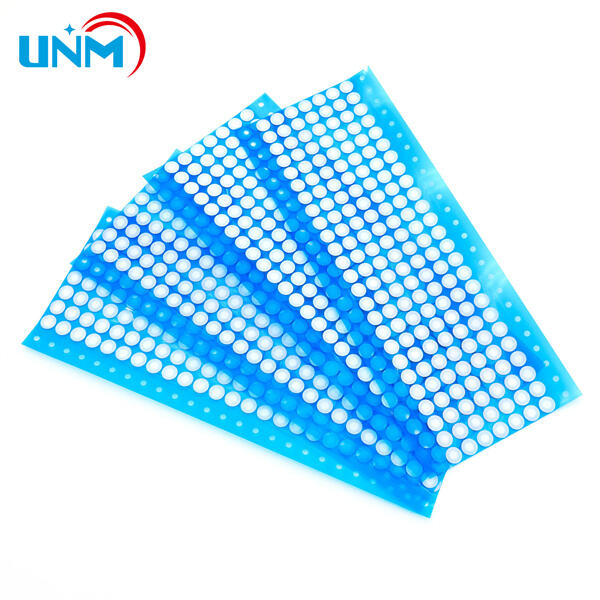

So, youmay wonder how ePTFE venting works. Including the acronym ePTFE, wherein PTFE stands for polytetrafluoroethylene. The fresh material is a type of plastic that has been "pulled and baked" to create something like mesh or net. The microscopic holes in this mesh are too small for all of those pernicious particles, but allow air and liquids to penetrate effortlessly. This allows air and moisture to pass but none of the bad stuff like dust or germs can. These holes can also come in different sizes to be tailored for individual products and industries so it is highly versatile and functional.

ePTFE venting is versatile in application and purpose. It has assets to create it in the style of things, so that they will work better and on many occasions can be used as a separate part. For instance, you see this in the ePTFE venting of caps for bottles that lets air out when opening. This works to keep content material up-to-date. It is also now in machine air filters, and helps to remove dirt of the road from going through your vents ise. On the other hand, ePTFE venting lines found in vents for outdoor gear (such as jackets and tents) provides a way out of moisture to keep the wearer comfortable. Because of the carefully engineered design and durability, ePTFE venting are widely accepted in various industries to improve product quality.

ePTFE venting makes many products work better and last longer. In phones or laptops parts can get too hot and ePTFE stops that. This is important because excess heat can break the device. ePTFE lets heat and moisture leave the device, so it lasts longer. In outdoor gear ePTFE lets the sweat leave the product. The product can become very wet and without venting, it can become very uncomfortable. In the car, engineering ePTFE lets the air easily move around, and the car spends less fuel, and it takes away drag. ePTFE technology makes our everyday life things work and feel better. Healthier With ePTFE Venting

ePTFE also helps to keep us healthy. In the hospital, ePTFE can make respiration and provocations to stop spreading the germs. It is important to protect the patient from the infection. It is also used in the food and beverage industry to keep food fresh and not spoil. It is important to keep everyone safe and not consume infected ones. It keeps our homes’ clean because they use it in the air filters. It is important to have clean air to reduce the risk of a respiratory disease.