ePTFE is a plastic but it's unique in the way that we can enlarge this material to create useful spheres. What is ePTFE Going to discuss how on technology of it, why the worlds uses and this elastomer so beneficial in industry also looking at its popular medical use as well aerospace. ePTFE is an interesting material with numerous unusual properties, making it a valuable material in many contexts.

Explanation: EPTFE - ePoliTetraFluoroEtilene. The material has tiny holes in it which makes the pass through liquid and gas efficiently. permeability is the name of this ability. The greater the number of holes, the more substances can get through. Because of this unique property ePTFE is useful in filtration and separation. It is even able to filter out the smallest of particles making it commonly used for clean water and air. It is used, for instance in biopharmaceuticals - medicines made from living organisms - and water purification systems that produce clean drinking water.

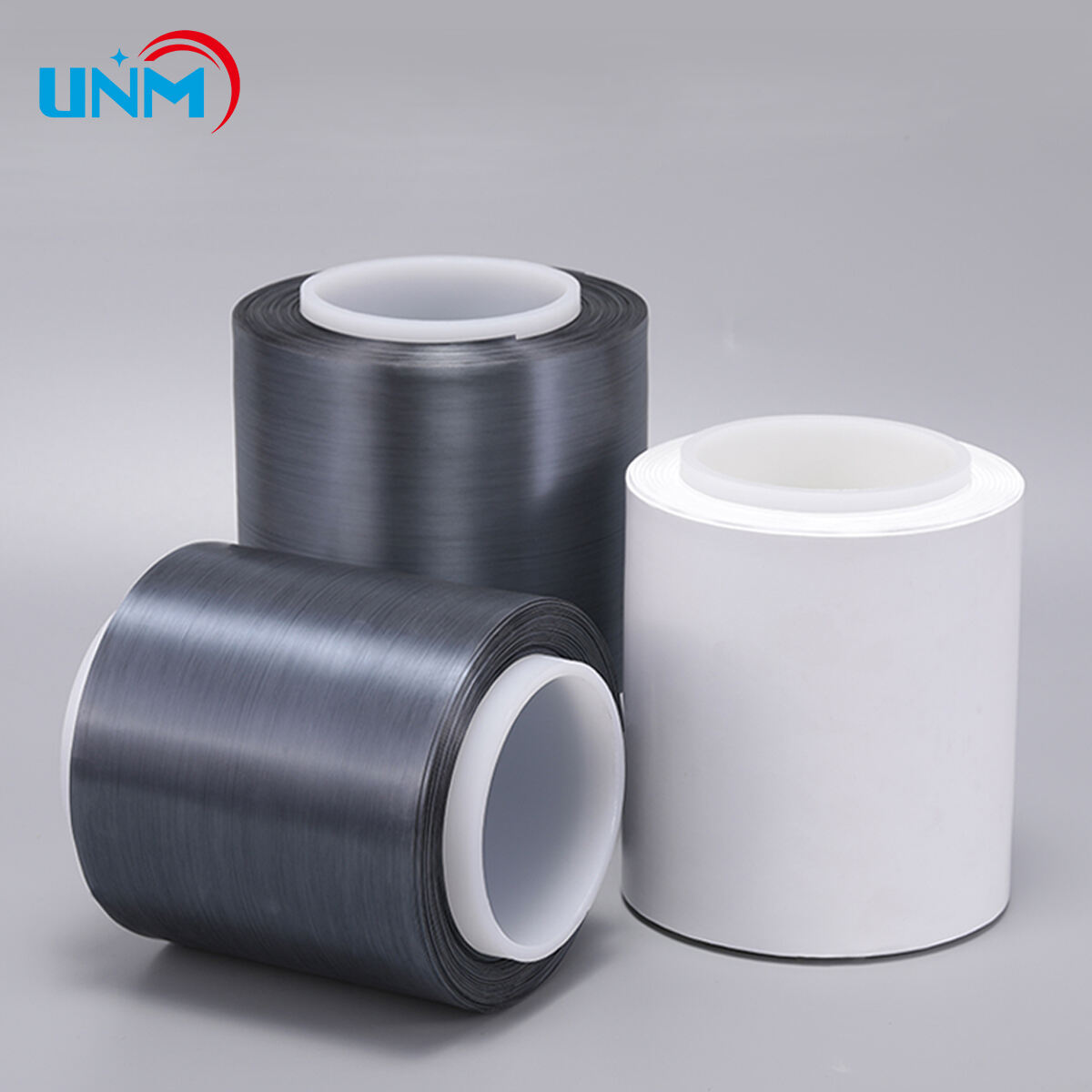

The invention of ePTFE fabric has changed the way in which a myriad number of industries work to an industry where its potential is undiscovered. You can create clothing, seals and gasketsair. Cold fires burn hot at the touch of a heat this cloth handles well in any weather condition so can be used for cold and warm locations. It is strong in every kind of environment, even when it gets too cold or hot the ePTFE fabric does not bow down. It is also chemically resistant, that means it does not spoil quickly in contact of harsh products. This makes it excellent for a variety of uses, such as insulation, filtration,hoses,gaskets and sealing. Today, industries trust ePTFE fabric for its multi-functionality and efficiency in dealing with difficult contexts.

Applications of ePTFE products in aerospace engineering is also very crucial. They are both very light and strong making them ideal for use in airplanes, spacecraft etc. Space in spaceship is premium, every ounce counts It is also worth mentioning that ePTFE products are lightweight in comparison with comparable materials, which has the added benefit of contributing to a lighter spacecraft overall and hence less fuel usage - something crucial for making travel more economical. They are also able to handle tough situations such high pressure and impacts that make them a dependable material for carrying on aerospace components. ePTFE is trusted by engineers for making gaskets, which are used to create seals and insulation materials that can take the harsh environment of flying high above Earth.

Our bouncing baby is made of safe medical grade ePTFE plastic as it clearly states on the condition sheet. This is such an extremely important sense because this deals with our health and safety. It coats cardiac patches to prevent clots, is used for smoother dental implants and creates artificial blood vessels. The U.S. Food and Drug Administration (FDA) has not objected to its use in these applications, calling the product "safe". This FDA has approved it for using in medical procedures, so that doctors and even patient can rely on such material. None at all-the point, after all, is to use it inside of our bodies-this makes medical devices the kind that your body won't have bad reactions too.

But it is also used to manufacture ePTFE gaskets which are again an essential product line of this marvelous material. They are used for sealing and insulation in many applications. ePTFE gaskets are pliable and durable enabling them to seal irregular shapes with no voids. It is important that the meeting remains functional in many different systems, thus flexibility guarantees a good seal preventing leaks and supporting efficiency. The gaskets are also resistant to a large quantity of chemicals and rust, rendering them ideal for use in many varying environments including automotive, aerospace and industrial systems. The reason that ePTFE gaskets are used in heating and cooling systems is because they can stand up to big temperature variations with little concern as a primary factor.