The hydrophobic filter membranes are specific filters, which find areas of application in almost all aspects of life. These filters can efficiently block water among other fluids, and are hence particularly advantageous in many distinct arenas of various industries. For many jobs these are an excellent example of doing things and better ways to do them with new technology. This post we will discuss what Hydrophobic Membrane Filter are, how they work, and why it is so critical for us today.

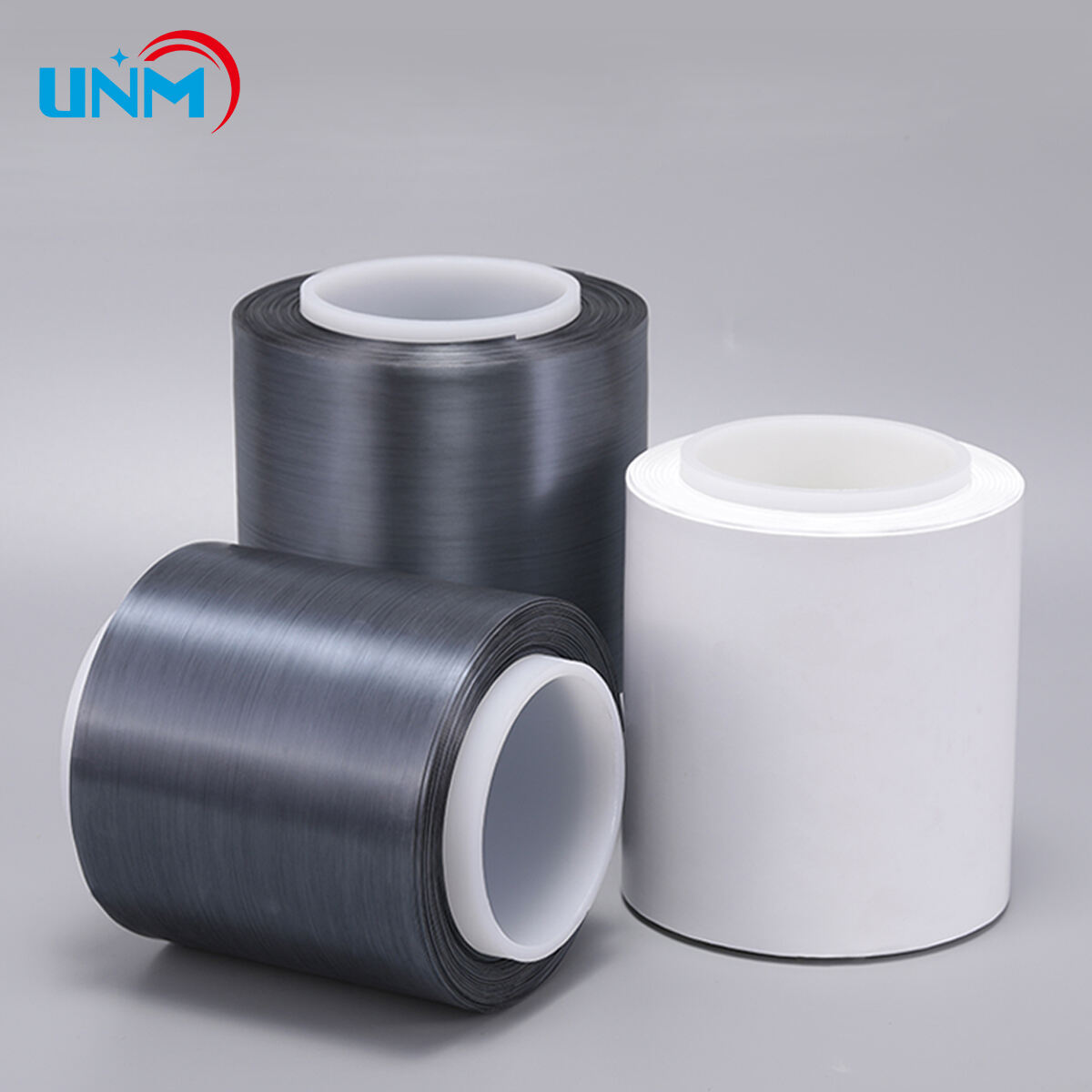

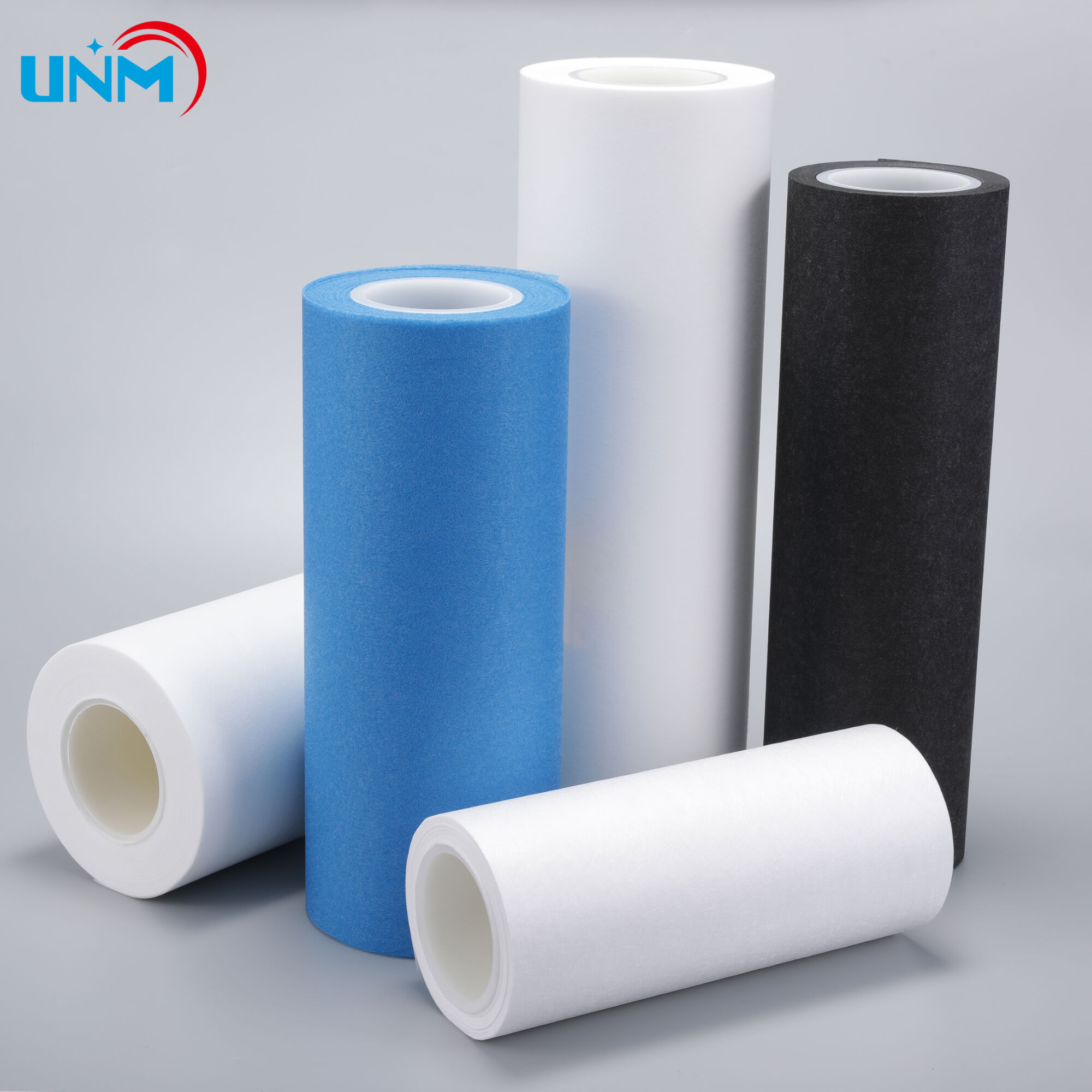

Hydrophobic filters are made of special materials that hate water full stop. If water hits it, Unique eptfe product pushes the water out of the way. The pores are very small on these filters and allow air and gases to pass through freely. But these holes are tiny and only let liquids through (actual bacteria or viruses can be much much smaller…). The specific design means they are useful for maintaining cleanliness and safety in different atmospheres, hence the reason why hydrophobic filter membranes exist.

It is only right to complete a few disgraces for hydrophilic filters and agree that hydrophobic filter membranes have really revolutionised the manner many businesses and industries clean and fielder their products. One example of this is how they are applied in water treatment plants to purify drinking water for people. They also form a sterility barrier in hospitals, which is absolutely necessary for patient safety and preventing the spread of infections. In the food industry these filters are used to eliminate impurities in various types of food products which help us not only for safe eating but also healthy. These filters have enabled people to perform tasks that were previously profoundly complex or just too pricey.

Chemically, the most distinctive feature of a hydrophobic filter membrane is its capacity to repel water. Their primary function includes the ability to absorb water and other liquid material, hence making them perfect for filtration in different manufacturing sectors. Plus, they're incredibly strong and tough to break. Tougher chemicals, higher temperatures, and less forgiving environmental conditions can take their toll without faulting Unique breathable ptfe film. This strength makes it a top choice in demanding environments where filters with less integrity can fail.

The applications of these filters vary across all kinds of areas. At hospitals, they are essential for sanitation and to prevent the spread of germs and diseases. Hydrophobic filter membranes are used in the food industry to purify beverages of all types, for instance fruit juice, beer and olive oil as well as other foodstuffs by removing undesirable substances such as bacteria that spoil the taste or might cause health problems. Used for filtering fuel and oil in the automotive industry, allowing engines to run at cleaner standards. Water treatment plants similarly use these Unique breathable ptfe membrane, as water passes through carbon before being sent to your tap at home, separating out toxins that would be harmful if consumed.

The hydrophobic filters membranes have a number of advantages and can be quite useful for various industries. They work great, in other words — meaning they get the job done well and fast. Besides, they can save as you do not have to replace and maintain filtration eptfe membrane often. They are used to remove grime, particles and other impurities from liquids and gases which is why you get clean products in the end, that fly well with what we use or consume. Moreover, being durable in nature, they stay for a longer time and hence are a cost-effective accessory making them an ideal investment by businesses.

These are found in all sorts of settings and industries. They are essential in hospitals to keep clean and control the spread of germs. Along with the food industry they also use to confirm that the drinks freshly squeezed fruit beverages or beer to be free from any additive substances. These eptfe air purification membrane keep fuel and oil clean in engines, which is important for maintaining engine performance and longevity. Hydrophobic filter membranes also have a major function in water treatment plants for safe drinking water.