Breather vent plugs made of plastic are the tiny yet significant components that ensure machines work well and efficiently. They are plastic plugs that come in different shapes and sizes to fit various types of equipments. One of their primary functions is to allow air into and out of the container, while keeping things like lint or dirt from entering. As said before it is very important to have this done so that the air inside stays clean and hence work properly while not damaging anything.

Examples are in factories and other places that use machinery, breather vent plugs need plastic. If this is not repaired even worse can happen in the long run because dirty air will enter your machines. This can often lead to problems like blockages, rust and even harm which devices. Machines run better when the air is clean. The same is true of machines that require clean air (e.g., hydraulic systems) as well. If the air is dirty, this whole system could fail costing potential delays and expensive alterations.

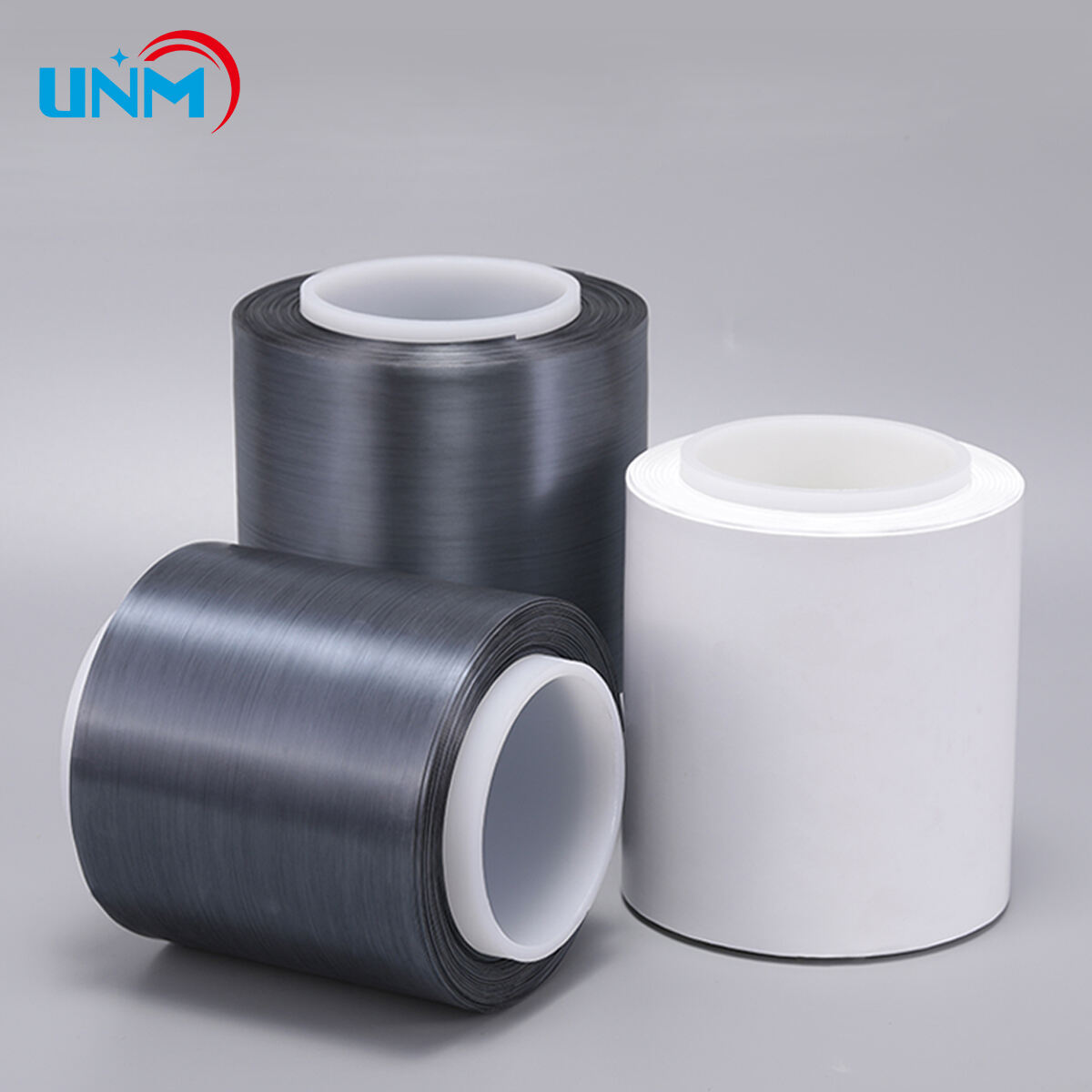

A plastic breather vent plug lets air in and out of a long-serving machine, while preventing dust from going inside. It typically consists of two main parts, the plug and a filter. A filter using a unique material that permits air through easily but will trap particles from entering it. It acts as a type of –guard, which catches some dust or something else unwanted from reaching the machine and making it into an issue.

The plug is used to seal the vent hole of the machine so that it fits perfectly. Beneath are a few functions (why use this product)? Not to mention, its light weight but strong properties mean it can be swarmed by busy indoor factory application. A plug serves as a seal to the machine so that air cannot escape but can come in when demanded. Crucial for maintaining the proper pressure and airflow as it pertains to that equipment.

Today, there are a wide variety of plastic breather vent plug s available to the general market and each one is designed with specific applications in mind. Now there are some plugs in machines working at high pressure, other than a few plugs that can be already used for low-pressure machine constructed. Also, some breather vent plugs are suited for extremely hot or cold temperatures whereas others perform best in moderate conditions. You must select the correct sort of plug relying on machine compliance as mistaking it for performance can lead to purchasing problems.

Selecting The Right Plastic Breather Vent Plug For Your Machine Take some time to consider what exactly your machine requires in a plastic breather vent plug. If you are not certain about which of them is the best option, some own examples can help to guide - or even if for any reason they do not serve as a parameter that suits your lifestyle.

Step 6: Measure the size of vent holeFinally, read what is traded by your Dev. machine through Vent Hole Size Related By doing this, you will be guaranteed to have a tightly fit breather vent plug for zero leaks.