There are a variety of ways this is conducted, and one well-known process to assist in separating impurities from various main components (sort liquids or even gases) would be membrane technology. These are used in many other aspects of life-from medicine to food production and electronics. The magical name for the special type of membrane that has totally revolutionized this process is PTFE porous membrane. This membrane has some very special characteristics that makes it highly versatile for a lot of applications in different industries.

PTFE (Polytetrafluoroethylene): High-quality plastic You can take some aspects of PTFE for granted, such as the ability to withstand strong chemicals or high temperatures. In other words, it was strong enough for a lot of applications to prevent from getting broke or damaged. Also, PTFE is extremely low-friction so liquids will not adhere to it easily. Thanks to these excellent properties, PTFE is widely used in various industries, from making medicines to producing electronic devices. But it is even more useful when PTFE, as a porous membrane that allows some things to go through while blocking others.

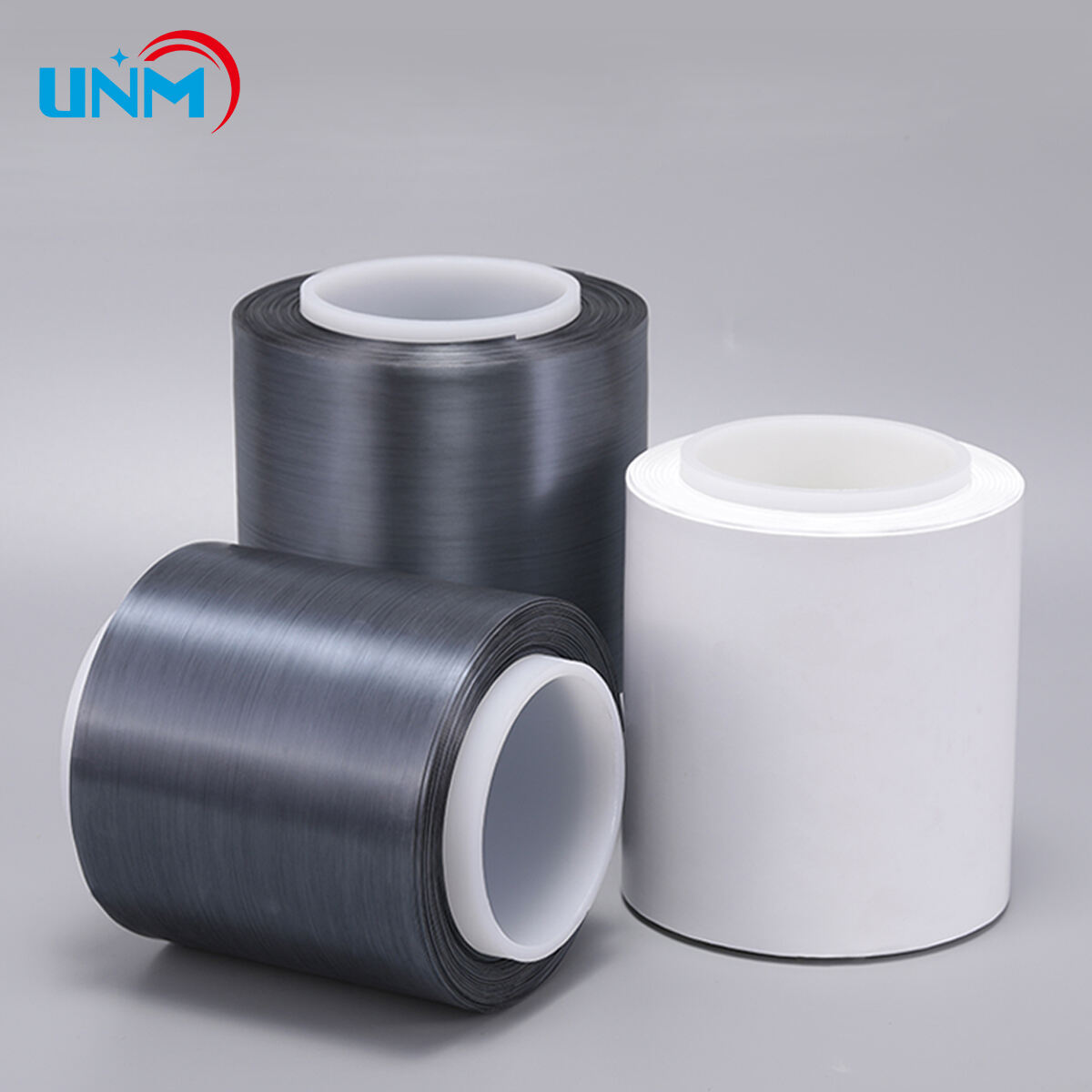

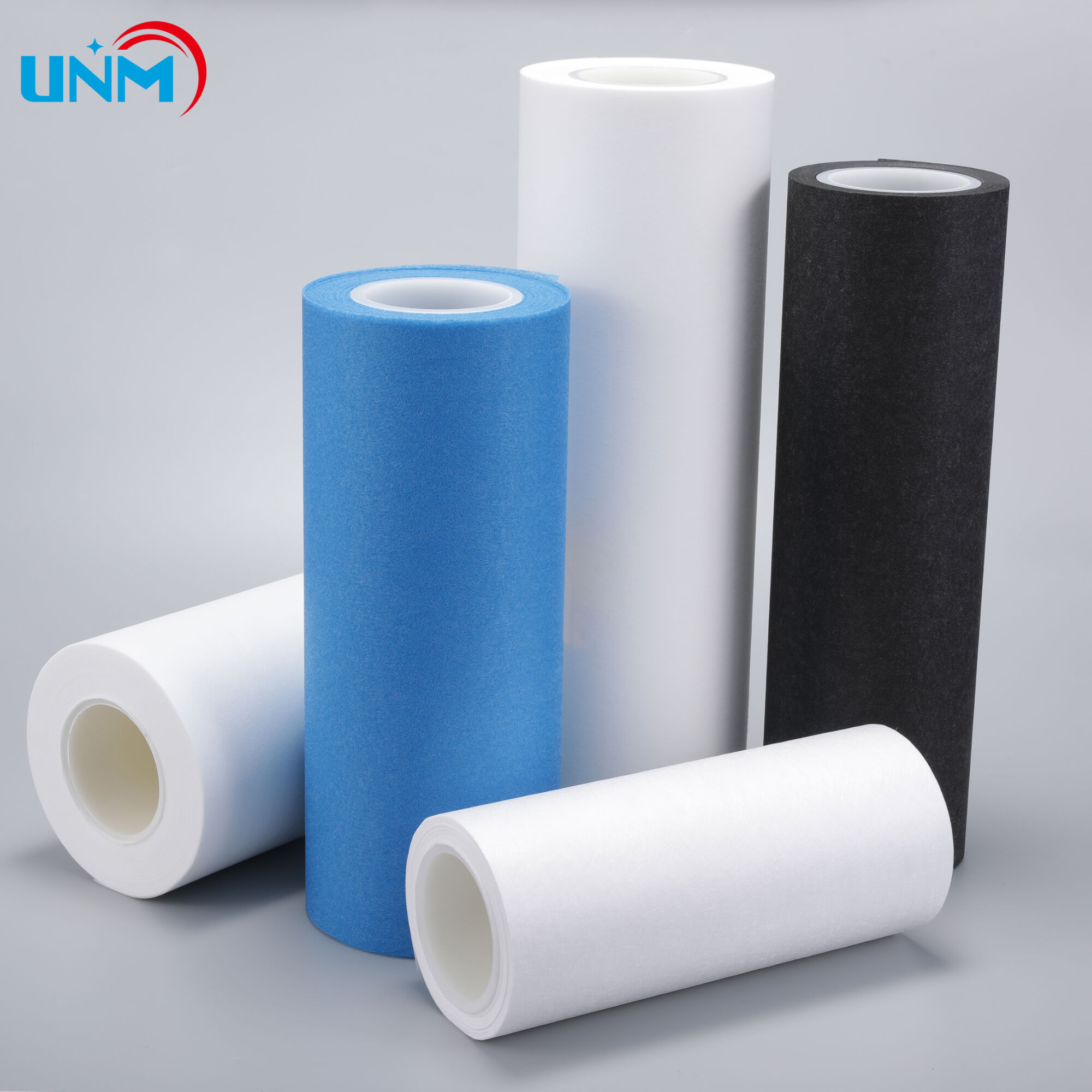

As permeable membranes made of PTFE, these materials have huge design flexibility - they can be in the form of flat sheets or curved tubes; even tiny fibres are possible. They can filter liquids and gases equally well as they are very flexible. They are also pretty robust membranes, so will last for a long time even under tough conditions like hot/cold temperatures and with very aggressive chemicals. Moreover you can have the PTFE membrane with holes of various size which makes it to filter different material perfectly. The ability to modify the pore size is critical for exact filtration and therefore PTFE membranes are suitable a number of very individual applications.

These have some special properties, the use of which allows for very good removal of un-wanted materials from PTFE porous membrane. Since they possess a huge superficial area, these compounds are able to seize and confine the smallest trace of matter that could move along with liquids or/and gases. It is particularly relevant to industries that require cleanliness, like medicine or food. Low surface energy - one other key aspect of PTFE is that it has a lower surface vitality with low friction and simple to clean(KERNPUBLIC-SILICONILTERS-5) This is good because it also enables the membranes to be reused, maintaining its efficacy. In short, this is just one of a variety of applications that PTFE porous membranes are ideally suited for in which robust and efficient filtration is required.

With such industries looking for technologically advanced, high-priced PTFE materials. Modern manufacturing capabilities have enabled us to produce PTFE porous membranes more simply and at a lower cost than ever before. Because of this, they are suitable for a larger variety of industries and uses. Besides, they are not only efficient in the field of filtration but also under research for others application like batteries, fuel cells or sensors. These latest applications amply demonstrate that PTFE materials possess a considerable market opportunity outside filtration.