Well, fermentation is a technique we use to produce many products ranging from medicines and yummy foods all the way up to fuels for our cars. They do this by growing something called microorganisms, which are tiny living things including bacteria and yeast. These microbes are crucial, they help to convert the inputs into things we can use. The main thing about fermentation is that you should separate the microorganisms from what they have made. This is where a unique plastic known as PTFE becomes beneficial.

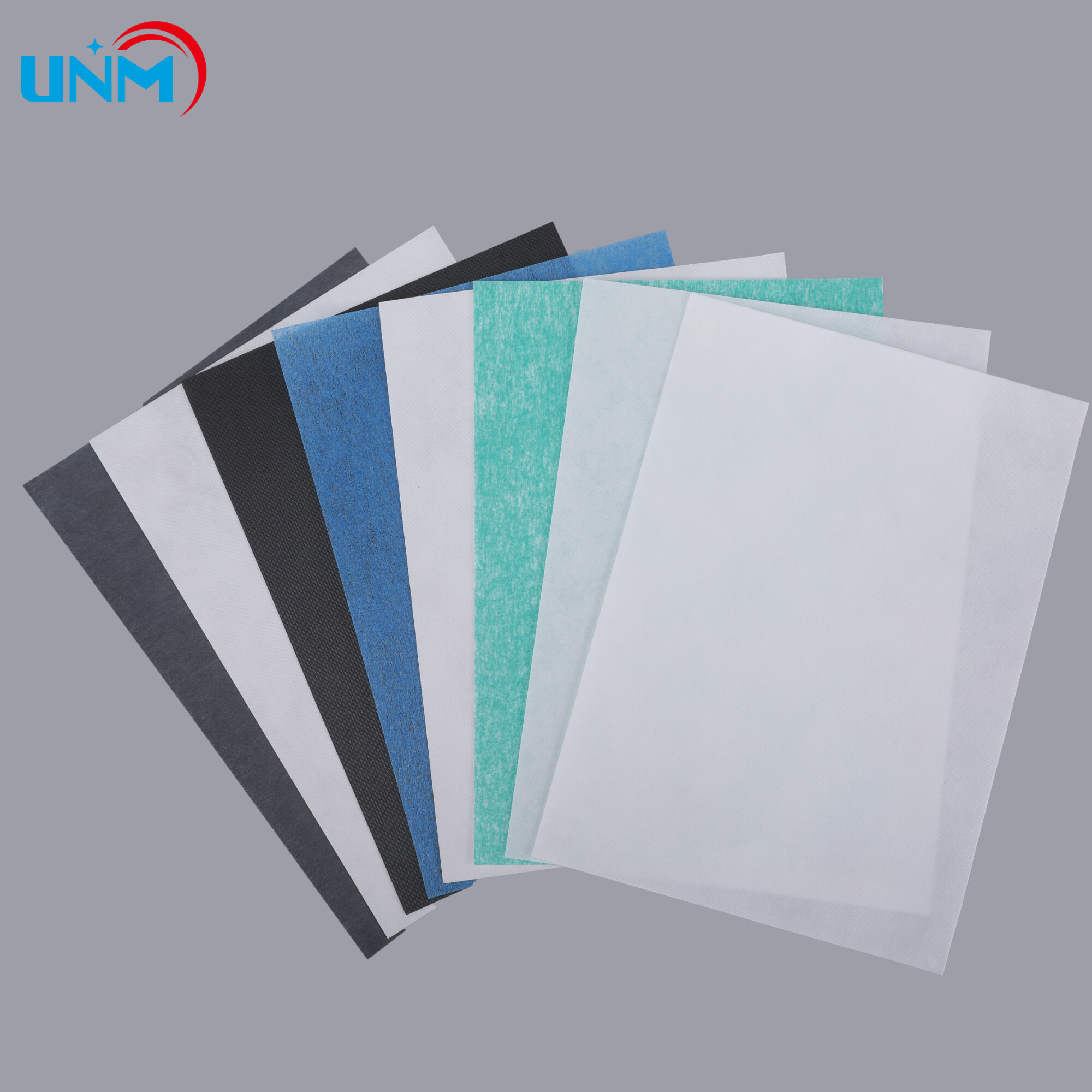

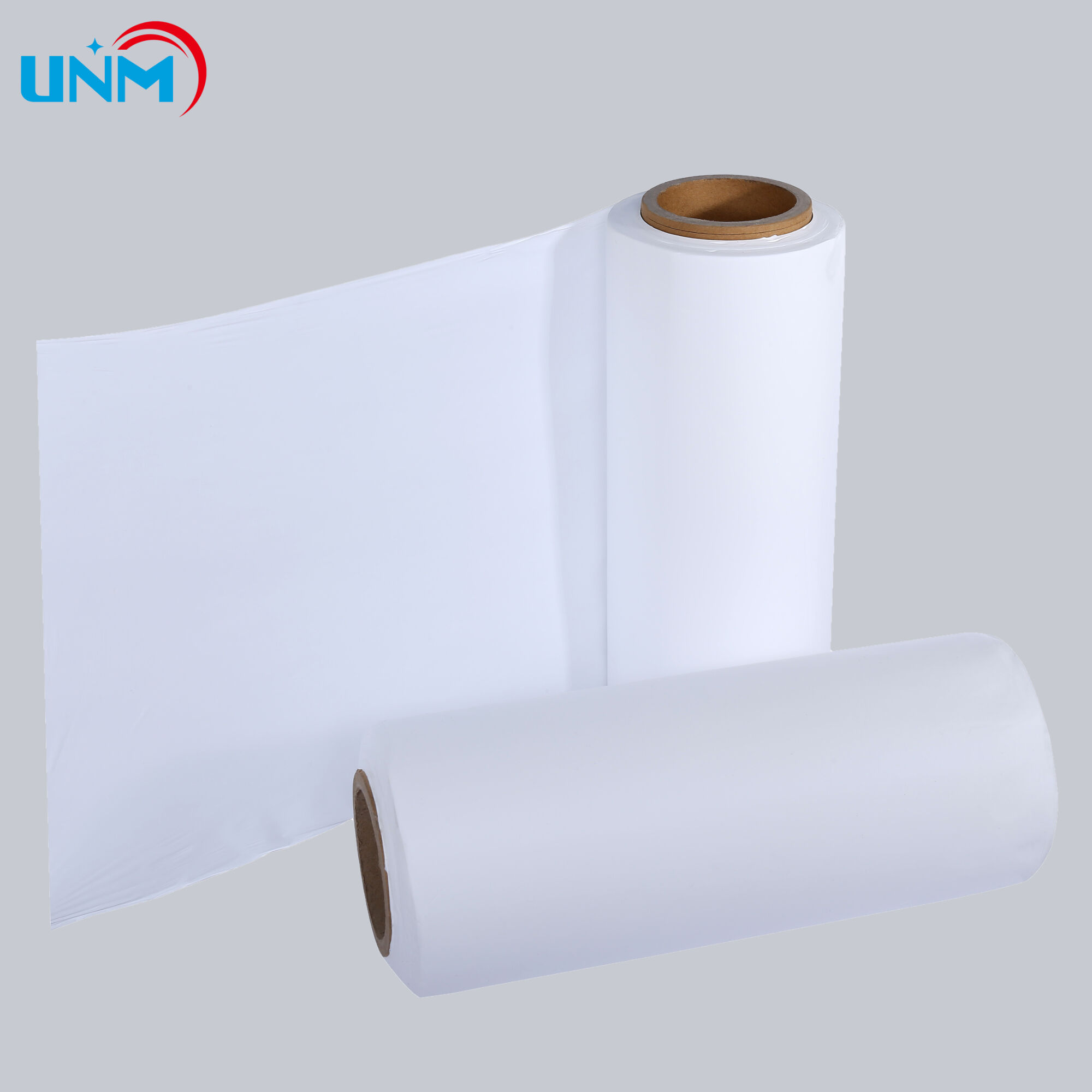

PTFE is a plastic that belongs to one of the most durable and strong kinds, as well as the Unique's membrane eptfe. And the fact that it can take high temperatures, repel water and not stick to any surface. These unique properties of PTFE have proven to be an excellent material for filtration bacteria out from the end product in Fermentation through a simple filter that ensures final Pure products are safe.

By incorporating PTFE into the fermentation, you can produce a better and greater quantity of finished product. One way it does this is by giving an optimal medium for the microorganisms to breed. This is why the PTFE membranes are ideal in creating a home where these tiny creatures can thrive without crowding each other for food and resources. This makes it possible for the ferment to grow and reproduce more efficiently, resulting in a better fermentation process.

PTFE also permits better control of the fermentation process, similar to the hydrophilic ptfe membrane filter developed by Unique. PFTE membranes help ensure that scientists maintain the all-important temperature and nutrient availability for their microorganisms during experiments. This control level has been implemented to ensure not only a good quality, but also the consistency of final products made each time. This stand-alone is important in industries where quality is king -where consistency with no variation can mean better products, for example food and medicine production.

PTFE: It can also be used to make the fermentation work faster and more efficient, same with Unique's eptfe dust removal membrane. As such, it is easier as well as faster to use PTFE membranes for the separation of microorganisms from a final product compared with older conventional methods. This means that it takes less time and require few efforts to complete the work which is very helpful for industries who wants continuous production of their product on a large scale comparatively.

In addition, PTFE membranes are also used in an exclusive process by the name of continuous fermentation, the same as ptfe liquid filtration membrane made by Unique. It is the process in which microorganisms are continuously being added or removed from fermentation chamber. All of this is in contrast to bulk fermenting as you tend to do it all at once. The PTFE Membrane is the key that they use for continuous fermentation as it allows them to separate the microorganisms through out disturbing whole practice that helps in making the process smooth.

PTFE membranes also provide the ability to have improved control over fermentation procedures, as well as the Unique's hydrophobic ptfe membrane. So that the end products can be more predictable in their quality, which is both for producers and consumers a great strong side. Also, PTFE membranes are self-cleaning and can be maintained for numerous cycles which saves resources and reduces waste. This is a twofer: Mother Nature and the companies can get to win.