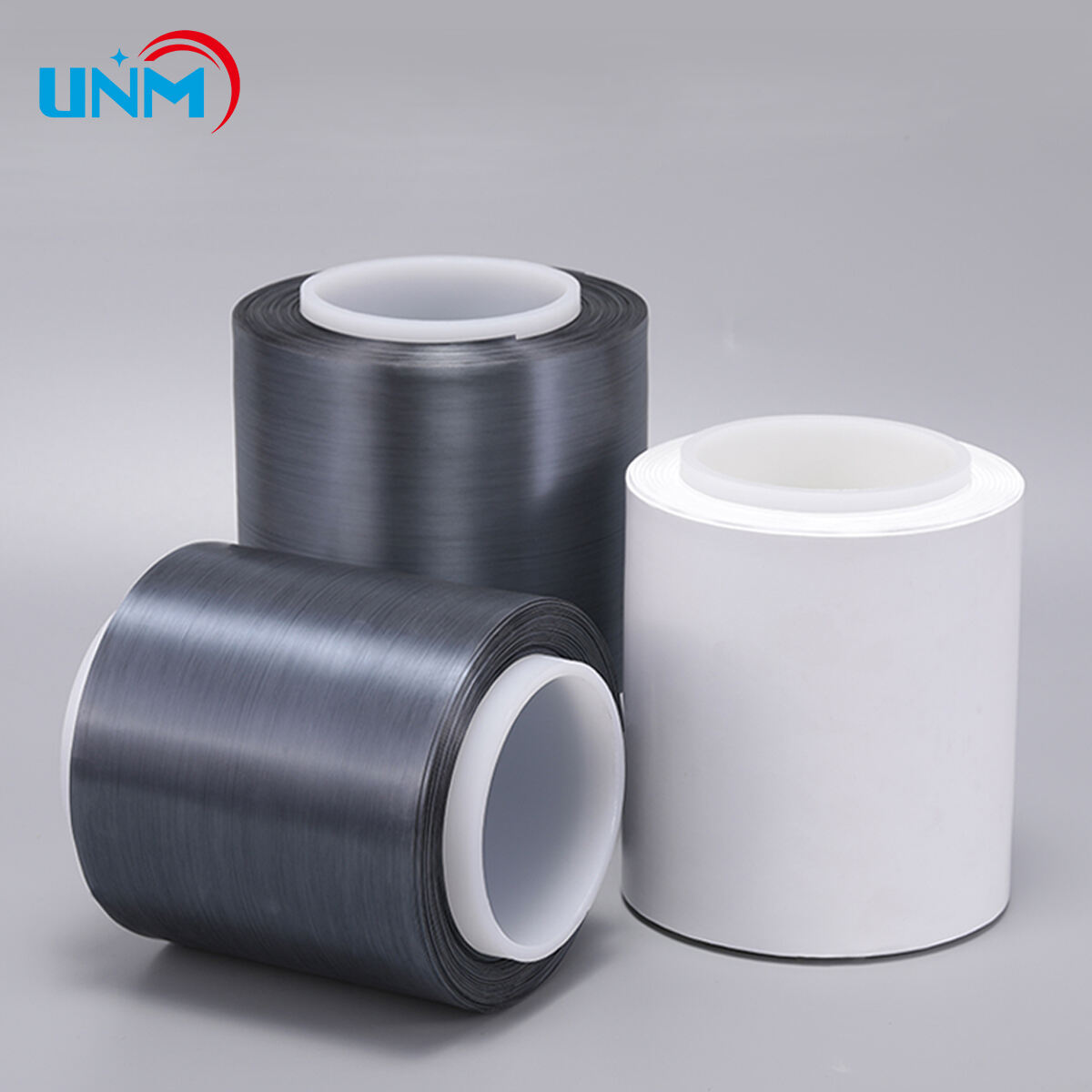

Before we go into the features of PTFE material, let us discuss what PTFE stands for. Polytetrafluoroethylene-also known as PTFE for short This is the great plastic that types in a different way. Because PTFE separators prevent materials from coming into contact with one another on many applications.

In the world of making chemicals, PTFE separators are an example that may prove helpful as a method to separate solids and liquids. The reason is because mixing them can create problems. On the other hand, in electronics PTFE separators are used to prevent different materials from touching each other. This reduces the risk of unwanted reactions or short-circuits that can make your devices malfunction.

PTFE separators have seen to be highly beneficial for batteries as well. The parts of battery : Batteri have two part 1. Positive side, 2.Negative Side Keep these parts apart, or the battery will fail to function correctly. The PTFE separators play the same function as a robust wall between these two components, this prevents them from coming into contact. When it does, well... It can lead to issues like a short circuit and no battery likes that.

PTFE separators are great because they can be so sturdy and robust. It won't corrupt while using high temperature which is very important because in a few usage, batteries can become hot. This provides exceptional life as well as performance from the battery, which gives us a dependable power source for our apparatuses.

This is crucial for medical tools as it ensures no negative reactions occur between PTFE separator and the human body. If the PTFE separator reacted with something in one's body, it would be problematic. Hence, PTFE separators are referred to as "safe for people" and safe because they can be in contact with human body (important especially from the perspective of application within various types of medical equipment).

PTFE separators keep the various segments of fuel cell apart so that the resultant chemical reaction will only occur where it should. This precise separation allows a greater potential to generate electricity and the entire fuel cell works better, thus being an extraordinary energy resource.

If you have unique requirements for the filters, select a separator that is made with specific PTFE components to ensure its effective use in your application. A good pick will ensure that the filtration is effective and as a result you get improved outcomes in your process with which you are making use of it.