What Are PVDF PTFE Filters Made of? These are tough stuffs carried with durable qualities and this is actually what makes such materials really,suitable for filtering unwanted substances. Since they are very powerful, they can take on the impossible filtering tasks that many ordinary filters would never be able to perform.

A PVDF PTFE filter offers excellent liquid and gas quality control for a wide range of industry sectors, from factories to hospitals, even water treatment facilities. This is accomplished by filtering out dirt, contaminants and other impurities allowing only the good portions to come out. This is particularly important in sectors where cleanliness matters most. These filters can also, for example, help to clean up waste products from factories which assists in maintaining the environment that surrounds us all safe and healthy.

The best part of using PVDF PTFE filters in this case is that they can handle severe and corrosive chemicals. This is particularly crucial for businesses that handle products such as medicine and food or beverage where security plays a significant role Filtering Water - These same filters can also be used to purify and filter water making it safe for consumption as well, by removing all contaminations present in the water!

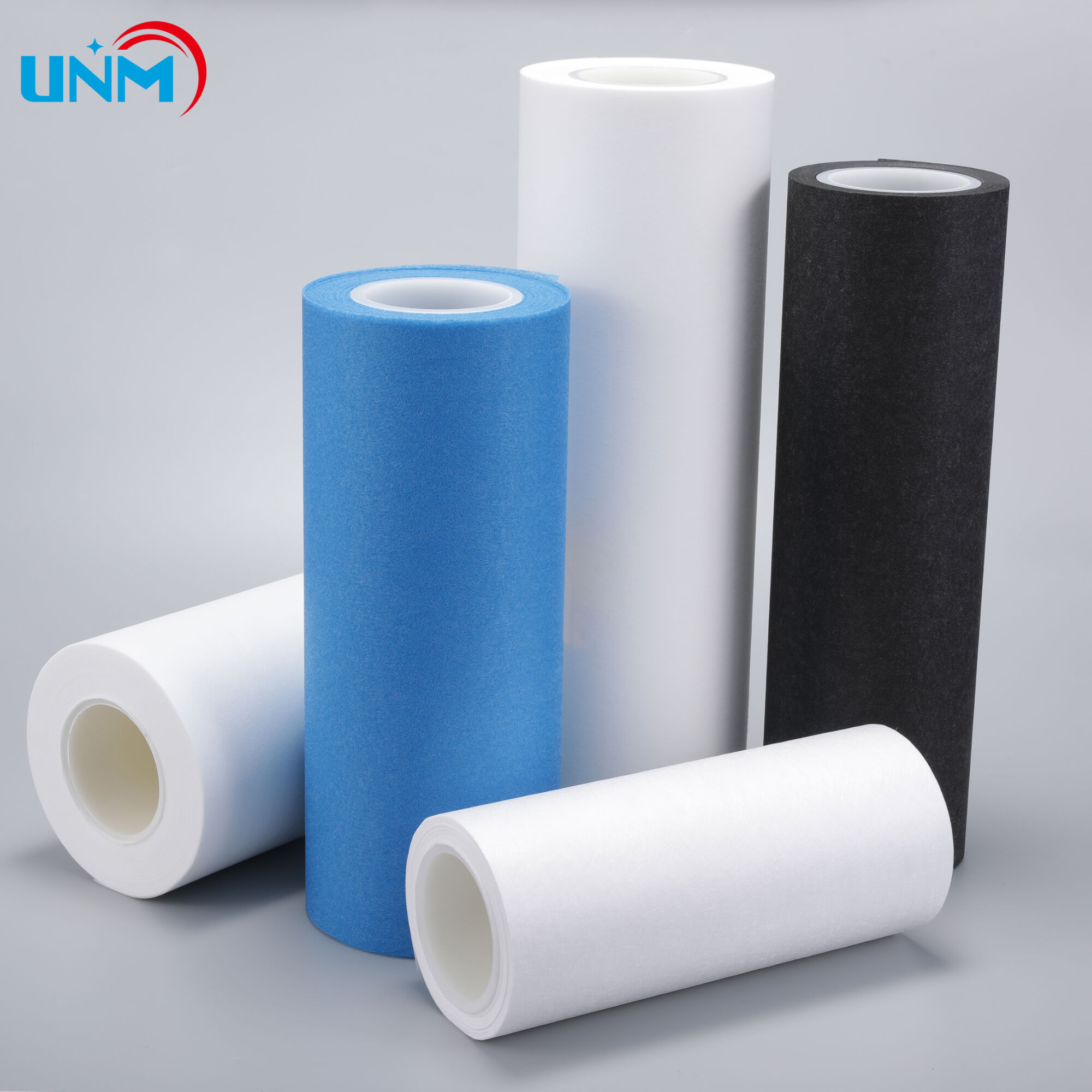

So called ultrafiltration, is a special process which removes liquids from solids (dewatering) based on size. The structure of the PVDF PTFE filter consists in extremely small holes that permit only very fine particles to seep through. This is why it becomes extremely useful even in hospitals when they have to draw out samples of blood and wish that their area must not get infected.

Chemistry and medicine requires clean products without any impurities. Where there is a presence of impurities or initial bad conditioning, then products can be non-useable and additional harmful for the human. So using PVDF PTFE filters is also very important for the filtration bases in these industries.

These are some activated charcoal filters that can help to safely remove dangerous germs, bacterias as well other unnecessary air particles. This is the piece where all of that water-based gunk and grime you are pulling out in your pureit dome kasi comes into to get removed by it unless rust finds its way first or a really old filterOrderId Turnout, which also happens. - The polytetrafluoroethylene part due to being waterproof does an excellent job of removing water based germs/bacterias efficiently from entered drinking stream[]. This is to make sure that at end of the process, products are safe for human and meets stringent quality requirements.

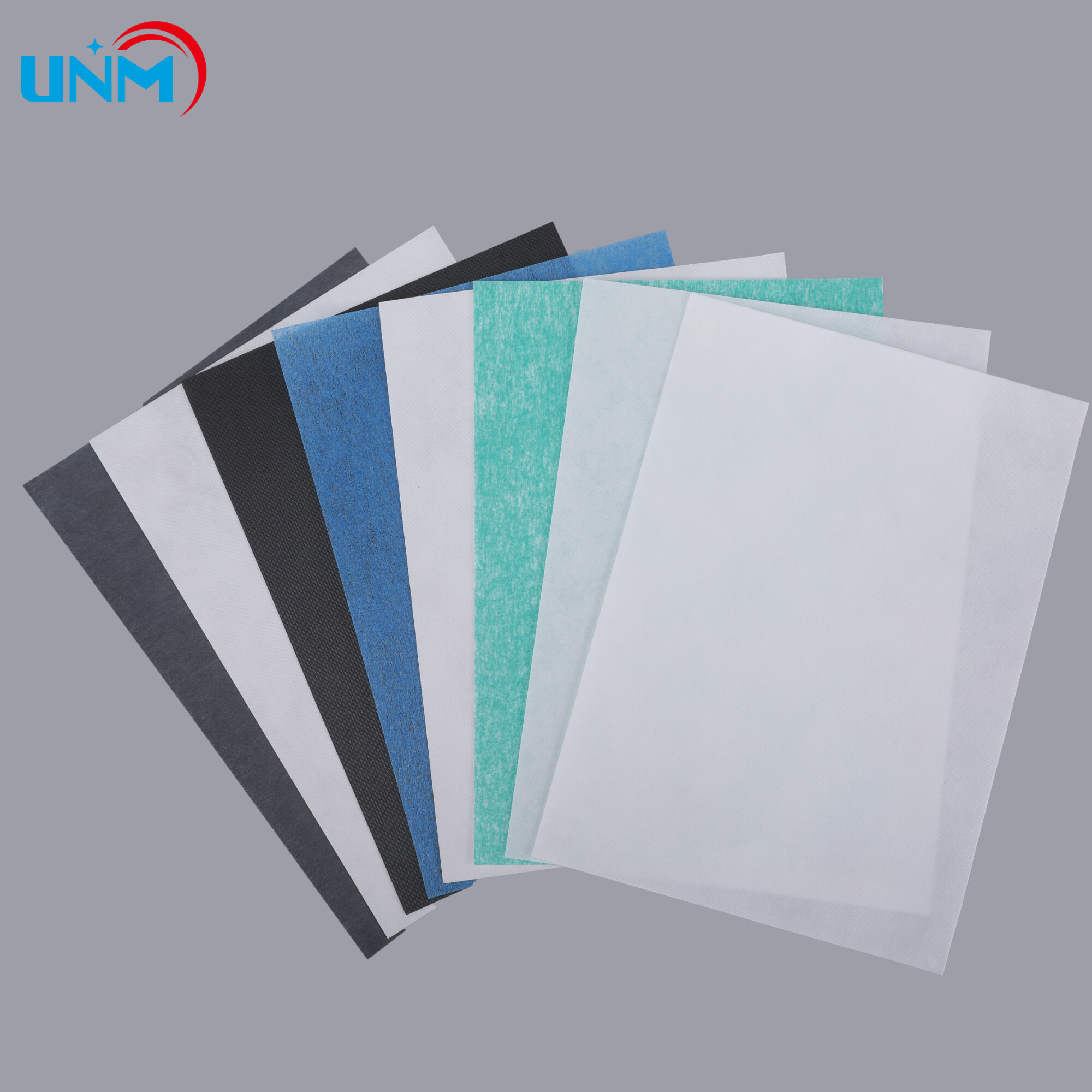

Its special porosity has a microporous structure which makes it works more efficiently. A thin body, large surface area to remove impurities efficiently and swiftly. It is AI's importance to the electronics industry, where cleanliness must be next to king lest there be a hitherto inexplicable issue with one of those ultra-sensitive components. Prevention of corrosion, failures and costly issues are benefitted due to a recommended clean environment.