When the persistent high temperature sweeps in, whether it is the operation of equipment in industrial production or the preservation of goods in daily life, they are facing a severe test. With its special material and structure, UNM ePTFE membrane becomes a reliable choice to deal with the challenge of high temperature.

Part.01

The core role of ePTFE membrane in high temperature environment

01 Thermal stability protection

UNM ePTFE film can withstand extreme temperatures ranging from -196°C to 260°C. In high temperature environments, it can effectively block the direct impact of external thermal radiation on precision components, preventing the performance of equipment from deteriorating due to overheating. For example, in the engine compartment of an automobile, the film achieves a balance between heat dissipation and sealing, avoiding high-temperature water vapor erosion.

02 Dynamic Breathable Barrier

The microporous structure (pore size 0.1-5 microns) of UNM's ePTFE membrane creates a one-way gas channel, which not only discharges heat vapor accumulated inside the device, but also blocks the penetration of liquid water from outside. This feature significantly reduces the risk of condensation in outdoor solar equipment and in hot shop ventilation systems.

03 Chemical corrosion protection

The resistance of UNM ePTFE membrane to strong acids, alkalis and organic solvents makes it resistant to corrosive gases and maintains the air pressure balance in chemical high temperature reaction devices, electroplating workshops and other scenarios.

Part.02

Application Scenarios

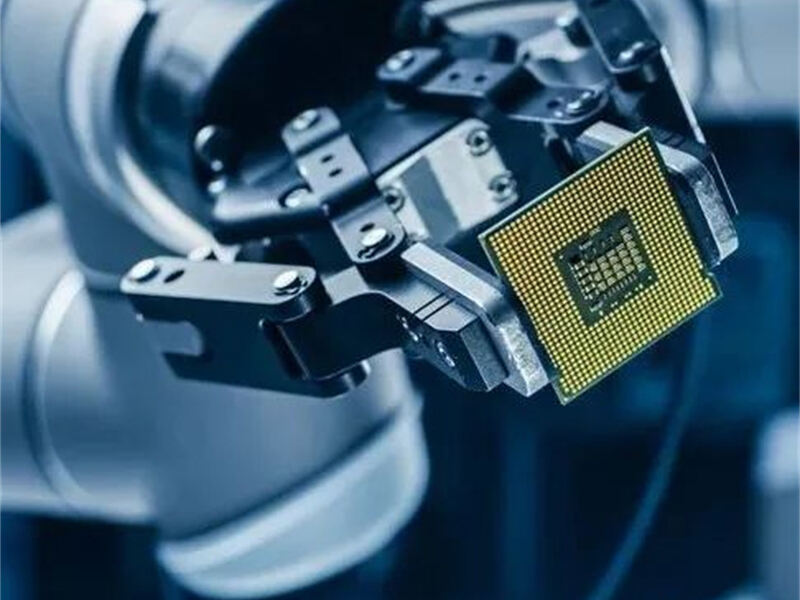

Consumer electronics: 5G base station heat dissipation module, folding screen cell phone hinge dustproof film

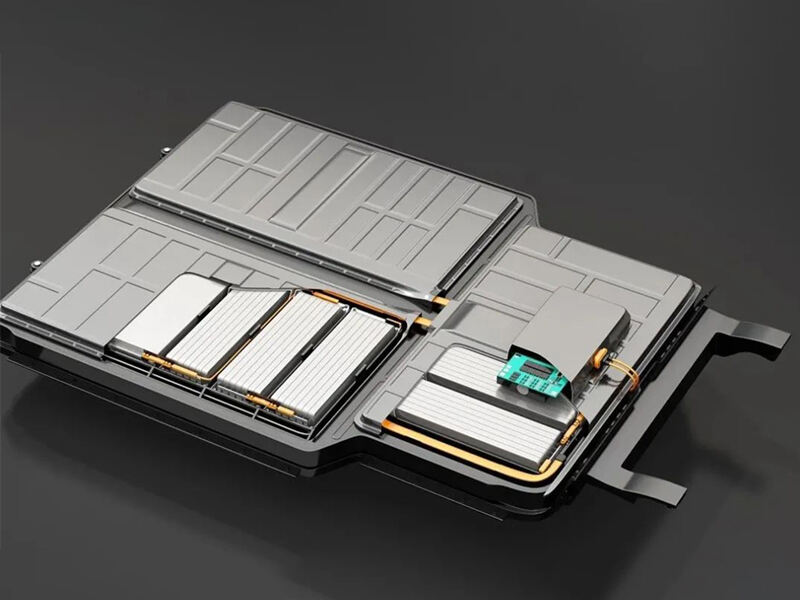

New energy field: power battery pack air pressure balance valve

Industrial equipment: high-temperature pipeline seals, steelmaking workshop sensor cover

Part.03

About Us

UNM ePTFE film provides a revolutionary solution for equipment reliability in high-temperature scenarios through its triple protection system of high and low temperature resistance, dynamic air permeability balance and chemical stability.

As global warming intensifies, these intelligent protective materials not only meet the stringent requirements for precision devices in the industrial field, but also show irreplaceable technical value in new energy, aerospace and other strategic industries.