When “ePTFE” Meets “New Blue Ocean in the Air”: Deciphering the Material and Safety Codes Behind Low Altitude Economy

Protecting Low Altitude Safety

ePTFE Pressure Relief Valve Protection Program

SUZHOU UNIQUE NEW MATERIAL SCI.&TECH. CO., LTD.

In 2025, the low-altitude economy is accelerating from the blueprint to the ground: Beijing, Sichuan and other places have designated air traffic demonstration zones, and the average monthly capital investment is over 1 billion yuan. In the airspace below 1000 meters, flying cars, eVTOL and other carriers to open the era of three-dimensional transportation, and lightweight and safety, is to crack the “let the transport fly” the core code - ePTFE membrane and pressure relief valve, is becoming the invisible pushers of this revolution. ePTFE membrane and pressure relief valve are becoming the invisible pushers of this revolution.

1. ePTFE membrane from the “plastic king” to guardian of the sky

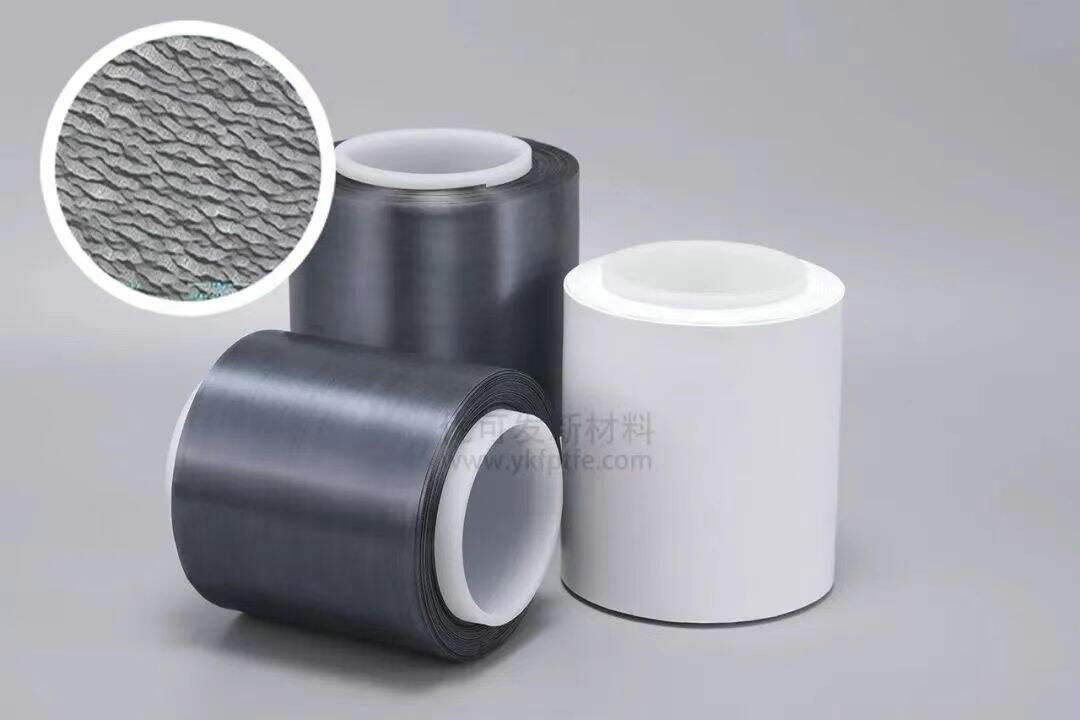

Polytetrafluoroethylene (PTFE) is known as the “King of Plastics” because of its superb corrosion resistance. ePTFE membrane, made by stretching process, unlocks three major characteristics by virtue of its nanometer-sized microporous structure: resistance to extreme environments from -269℃ to 260℃, waterproof and breathable, and lightweight and high-strength (with density of only 0.9-1.1g/cm³). These characteristics make it indispensable in outdoor equipment, industrial dust removal, electronic protection, etc., and it is moving from behind the scenes to the core in low altitude vehicles:

1) Lightweight fuselage

Replacing the traditional metal skin, weight reduction of more than 20%, both UV resistance and insulation.

02) Battery Safety Barrier

Acts as a pressure relief valve seal, preventing electrolyte leakage and rapid venting in case of thermal runaway.

03) Environmental guardian in the cockpit

Integrated into the air conditioning filter to filter low-level pollutants and protect cockpit air quality.

2. Airborne “Safety Valve” with millisecond response time

In the pressure system of the flying car and eVTOL, the pressure relief valve is the last line of defense against sudden changes in air pressure, power failures and structural damage. Its core lies in precise control: when the pressure exceeds the threshold (e.g. 0.8MPa), the spring/lever structure opens in milliseconds to relieve the pressure, and closes automatically when the pressure drops. Low-altitude scenarios impose stringent requirements: lightweight (Relates to the duration of use), resistance to high humidity and salt spray corrosion, and long service life - which is the key to combining with ePTFE membranes.

The “diaphragm-type” intelligent pressure relief valve created by the synergy of the two is 50% smaller in size, suitable for compact airframes, and real-time monitoring is realized through integrated sensors, which meets the requirements of European and American airworthiness standards (e.g. FAA Part 23) for multi-level protection.

3. Industrial Breakthrough from Material to System

01) Material Breakthrough

UNM has realized a new breakthrough in the performance of ePTFE membrane material, and the cost is 30% lower than that of imported materials.

02) Manufacturing Upgrade

A number of domestic enterprises have developed aviation-grade lightweight pressure relief valves.

03) Practical application

A domestic enterprise tests the program of “ePTFE membrane + intelligent pressure relief valve”.

The policy is also accelerating: in 2024,《White Paper on Low Altitude Economic Development》makes it clear that the airspace below 300 meters will be opened up in 2025 for “visual flight”, and in 2030, an industry scale of hundreds of billions of dollars will be formed. When the material innovation (ePTFE) and safety technology (pressure relief valve) to form a “two-wheel drive”, the commercialization of low-altitude transportation is no longer a science fiction movie scene.

4. Conclusion

The take-off of low-altitude economy requires “stargazing” imagination, but also “down-to-earth” technological attack. ePTFE membrane and pressure relief valve story is exactly how “hardcore technology” can empower emerging industries. “How to empower the epitome of emerging industries - when each piece of membrane can withstand the cold at 10,000 meters high, when each valve to keep the pressure critical red line, the human desire for ”three-dimensional life" can be truly transformed into a safe, Convenient air travel.

Perhaps in the near future, we will find that those “small parts” hidden in the corners of the aircraft have long been the “golden key” to open the door of low-altitude economy.

5. Technical Cooperation

We provide customized ePTFE protection solution development service for low altitude economy equipment manufacturers, welcome to contact our engineer team for detailed technical information and application cases.

(Professional technical support: www.unmptfe.com / [email protected])