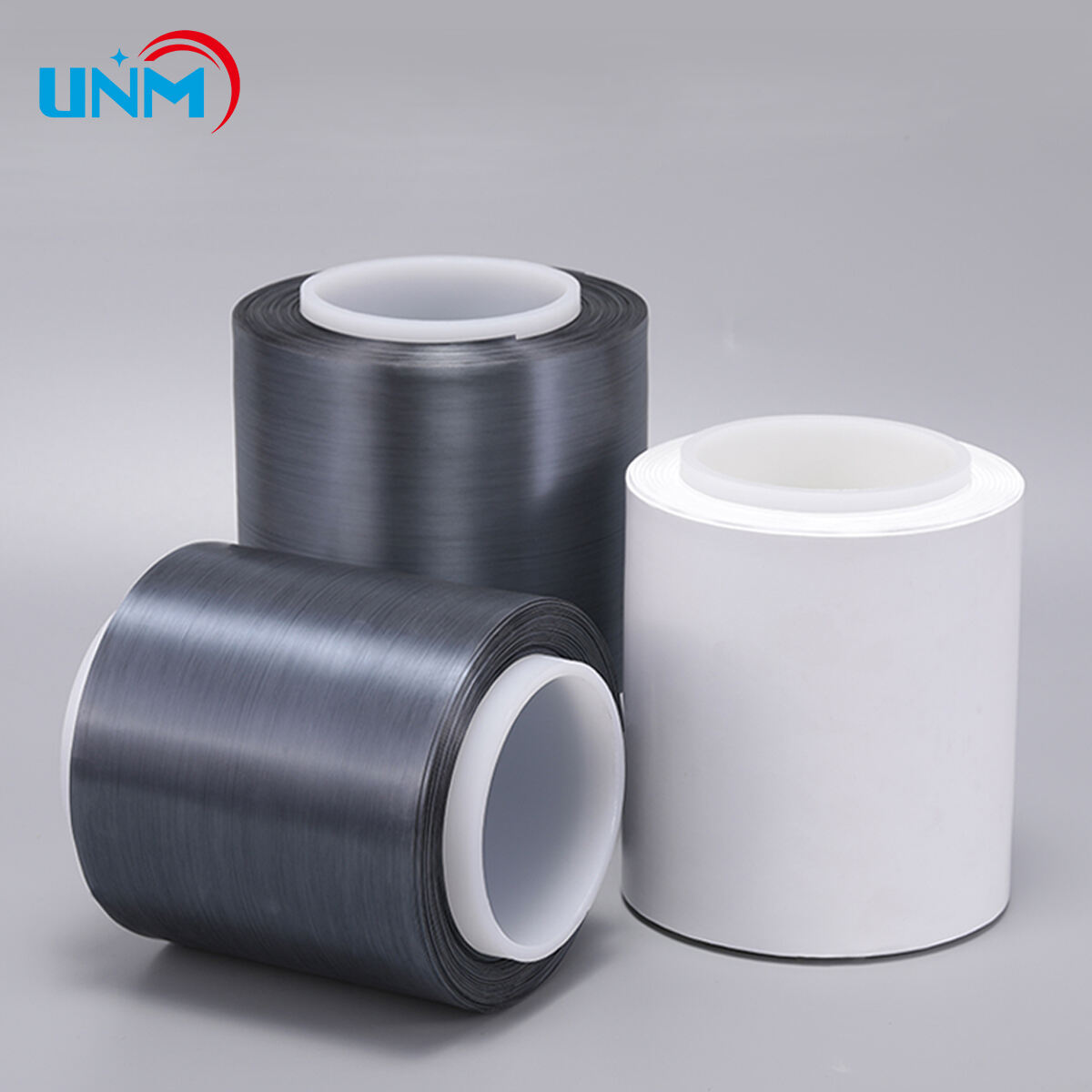

The black ePTFE membrane is a rare material that you will see being implemented in all of the different factories around the world as well. It is constructed out of a material called ePFTE (expanded polytetrafluoroethylene). This special process is used to heat and stretch another material, PTFE (polytetrafluoroethylene), to create this new stuff called RNTU. This is critical because it contributes to the ePTFE being so strong which allows for its widespread use.

The black ePTFE membrane is an excellent non-stick surface. The central pillar is more as the The highest matt finish known to man which means nothing will stick including oil or grease! This property makes it extremely useful for filtration and other applications in industrial factories. Think of needing to get your hands dirty and clean up some sticky mess… having a non-stick surface means that everything still gets messy, but you can more easily remove the bits at least. Very durable ePTFE membrane is even resistant to harsh chemicals like acids and bases. This chemical exposure is usually very harmful so the black ePTFE membrane can withstand them, which provides excellent strength and consistency for heavy-duty applications.

And the black ePTFE membrane also has an awesome performance in cleaning and fiber separation. They are of great use in these kinds of jobs, then eggs make sure that when mediums is passed it can separate solid parts from such liquid or gaseous stage. Let us say that you have a solution of sand and water, by having the membrane at one side which will capture all the particles of ascended. And, since it is anti-adhesive and some of the solid components do not stick to this material they will cause obstruction. This not-stick property is very crucial as it maintains the membrane operational. It does a good job with cleaning and separation in factories because it can hold up to strong chemicals.

The black ePTFE membrane is very effective at blocking dirt and water from entering sensitive areas. Preventing unwanted water or other substances from entering equipment or work areas is vital in many factories. The ePTFE membrane will be black and create a strong barrier, preventing these from getting in. Non stick property makes sure that water or dirt does not adhere to it preventing the barrier from being effective. At the same time, it is strong enough to last against just about any conceivable problem that might arise from external influence. As a result, those looking to safeguard their motorcycles and components suggest S100.

Lastly, the black ePTFE membrane is used in the most difficult situations. The ePTFE membrane is a great answer for areas where the materials must endure severe cold or high pressure and other extreme environmental stresses. It is perfect in these instances where other materials break or fail because of its non-stick, solid and chemical resistant properties. That black ePTFE gets put to work at an industrial factory that operates in extreme heat temperatures, and the membrane can survive even higher temperatures of those without degradation.