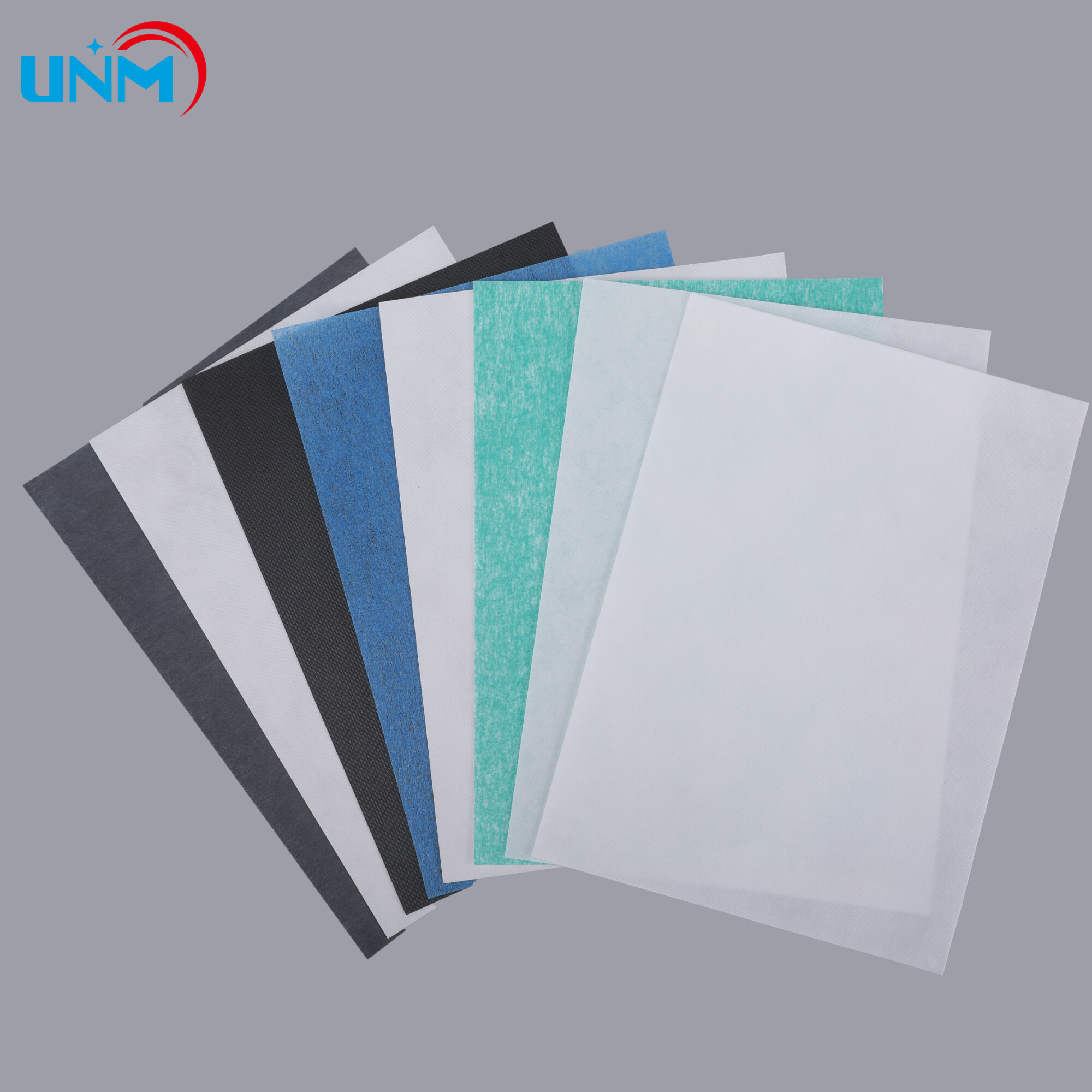

PTFE hydrophilic film - that's a unique category of the movie, with all types of new tricks. While, the material of this type of film is PTFE(Polytetrafluoroethylene). The beauty of it is that if keeps from sticking to other stuff, even when the product happens to get wet. As a result, it can be used in many applications without becoming clogged or causing issues.

Very strong and sturdy - this is another very positive point about the film. It can withstand the high heat and pressure of an automotive engine without failure. Which makes it great for harsh environments, like factories or hospitals where things can get pretty hectic and stressful. Unique ptfe hydrophilic organic film will continue to operate, it can be performing at top form (clean) no matter how bad the conditions become.

How PTFE Hydrophilic Film Can Be Helpful to More Industries. Medical devices Use cases of this film are one the biggest in medical end (Application). Able to cover essential instruments such as catheters and stents used in assisting patients internally with a plethora of health issues. The Unique breathable ptfe film is also injected onto these devices to prevent blood clots. This is extremely essential in the end for affected person well-being as blood clots can certainly turn into serious and even perilous repercussions.

This film is capable of showing many years but not recommended for factories and industrial purposes as well. It can cover pipes and machinery that touch fluids. This helps in preventing them from rusting and losing their efficacy. This is very helpful to workers, as it ensures that equipment does its job well rather than being put out of work due to damage. When machines fail it can slow or stop production.

PTFE hydrophilic film has various other applications, which is then good to be used in different areas. The good points are that it absorbs liquids like a towel pride. This is critical in medicine and factories where rapid uptake can be important. In a medical setting, this means that the faster you can drink (or absorb fluids), the better doctors will be able to do their job.

Moreover, PTFE hydrophilic film also plays a critical role in medical instruments. One application is to cover medical devices, such as catheters and stents so that they can function safely and efficiently. The coating is designed to discourage blood clots from forming on the devices, a potential lifesaving feature. By coating medical devices with this polymer, they are assured in use and complications for any treatment is decreased.

There are factories as well as industrial area which is important too where PTFE hydrophilic film is used. However, Unique ptfe film can be used to coat pipes and machinery that are in constant contact with different types of liquids. This layer of protection prevents rust and other forms of damage which in turn keeps everything going smoothly. Many businesses are only able to function day in, and out thanks to great machinery keeping them running.