PTFE film is a highly sought substance, as it works wonders for various tasks. Nowadays, almost all movies are more or less the same but this is where Research has produced something unique which you cannot find in other materials. Understanding these attributes is essential as they explain why you would use an Expanded PTFE Film in many ways.

What makes Expanded PTFE Film so great is that it can withstand heat and powerful chemicals. This means that it is safe to use in the presence of very HOT things (fire) or around STRONG chemicals without injury or destruction. For example, in certain factories these material are used where the temperatures very high or strong chemicals are there etc.

Expanded PTFE Film is a brilliant rubber that has many usages and can be found in your engines, pipes or any other machinery. Unique Expanded Polytetrafluoroethylene membrane seals help keep the liquid from leaking and protects everything works correctly. It is also used to make prostheses and the like, that remain in people who are unable to walk.

In a medical sense, there is the fact that Expanded PTFE Film enables light yet strong prosthetics to be produced in medicine. They are also individually manufactured to fit each person very closely so that they can be worn as the equivalent of a clothing comfort. For individuals who depend on prosthetics for everyday functioning, comfort is key.

The power in the expanded PTFE farm is replacing traditional type gasket materials such as rubber and cork through factories, stream light. Indeed, this Unique expanded ptfe is occurring because of the fact that Expanded PTFE Film has a significantly longer life expectancy and will not wear down as quickly. It also offers greater resistance to heat and chemicals than these other materials.

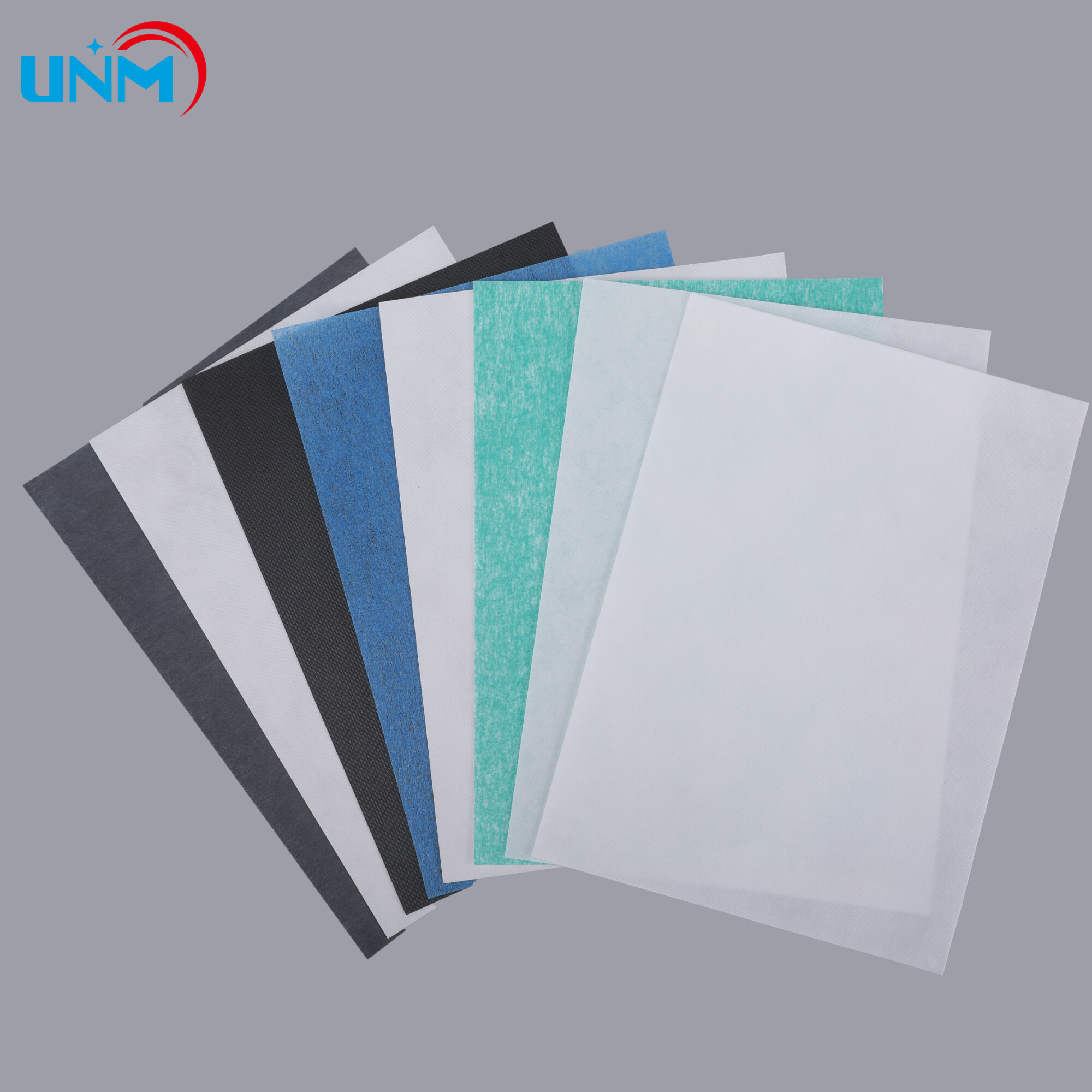

Expanded PTFE Film finds application in a variety of industries due to its strength and flexibility. As an example, it can be utilized in sealing pipes and engines to stabilize leakage. It is also used as a tool in the production of chemicals and drugs, where particularly high strength and reliability are required.

It also inherently withstands heat and chemicals. Therefore, it is the best option in jobs having extreme temperatures or severe chemicals. With the use of Unique expanded polytetrafluoroethylene eptfe, workers can rest easy that no matter how difficult their environment may be, materials will not fail.