So now you are thinking, what on the earth is microporous PTFE? This is a unique material that works as an agent in hundreds of jobs, from helping in hospitals to being used for making clothes. But what is it exactly? A microporous material made from the polytetrafluoroethylene, shortened PTFE. This is an amazing material, that can withstand very high heat and strong chemicals without breaking down.

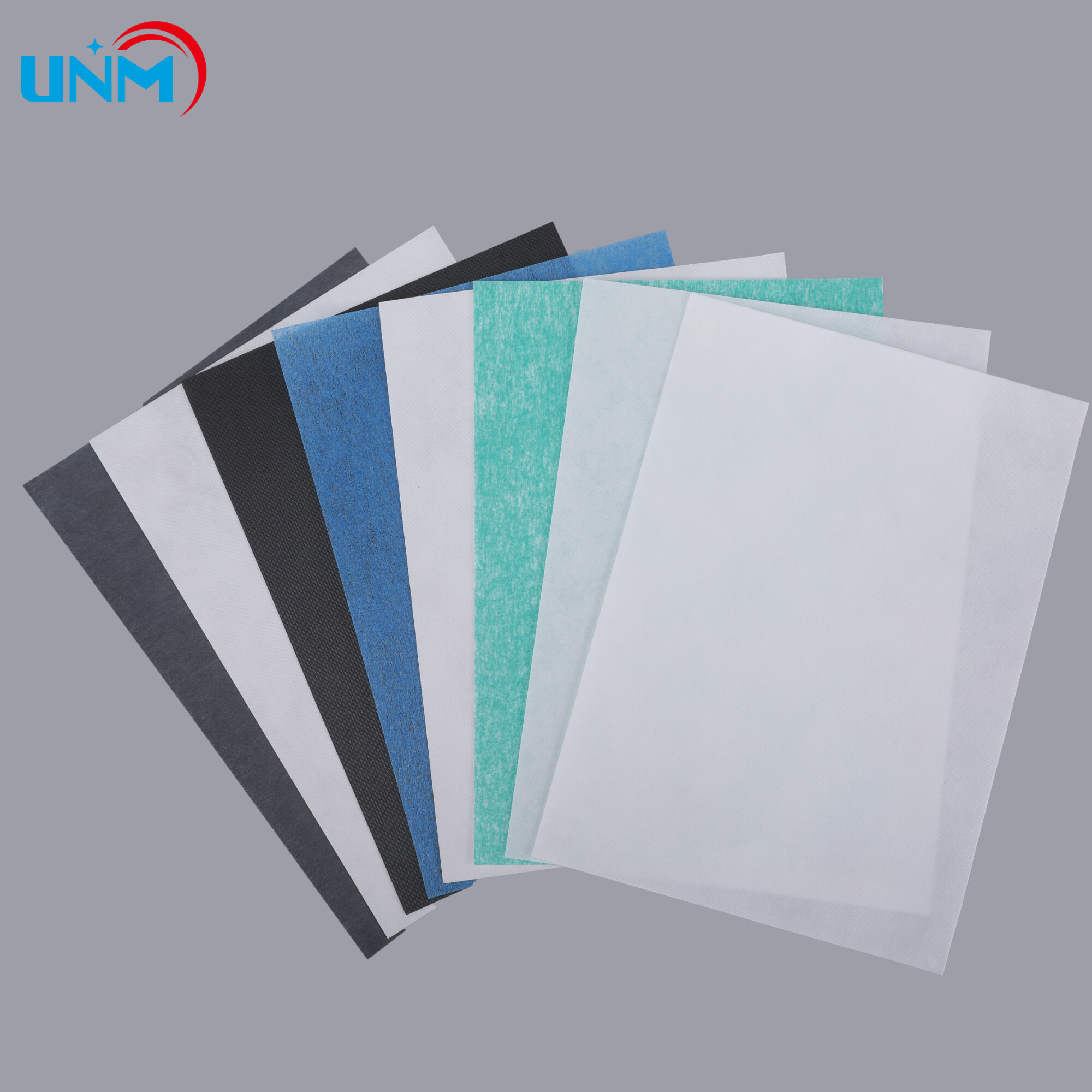

The microporous PTFE layers are simply quite thin and light, but very protective. Weaving Together...these layers possess a wide range of exceedingly small spaces that appeal to oxygen and dampness, normally they do not allow anything larger than germs or dirt passable through. This is why they are excellent for medical products such as bandages and facial masks. This is the same with a face mask, doctors and nurses want it to be able to let you breathe easily but block out anything else that can get them sick.

You might have heard already that microporous PTFE is also changing the way factories filter stuff. It may be utilized in the splitting of liquids and/or gases during producing a wide variety merchandise. Normal filters get clogged quickly; therefore, need a lot of cleaning which is time-consuming and delays work. Standard PTFE membrane filters should be strong, anything but difficult to deal with and easy to use But microporous PTFE channels have been somewhat an extraordinary case in light of the fact that they can essentially clean up after themselves. That way, factories can keep churning along without halting production frequently for repairs.

Microporous PTFE is a versatile material and has wide applications in various fields. So, other than hospitals and factories it is also used in electronics the air planes also on your clothes. One example of such fabrics is microporous PTFE that allows air to get through but serves as a barrier against water. This also means that they are ideal for outdoor activities such as hiking, camping and other adventures where you may get damp but still want to remain cosy.

These are especially loved by athletes and outdoor enthusiasts who prefer the breathability of microporous PTFE fabrics. They suck because they make sure to keep you wet when it rains. This fabric lets the sweat from inside out that gives you a cool and comfortable feeling while it does not let raindrops get in, they are also stretchy so helps with your mobility especially when starting wearing all of it around.